PIS(Production Information System) is an intelligent control system focusing on data collection, monitoring and statistical analysis of ERW tube mill lines. The system realizes the transparency of workshop production information, optimizes enterprise lean process management and decision making, and improves production efficiency. PIS is imposed of MDC, PQDM, EMS, Dashboard & Mobile.

MDC(Manufacturing Data Collection & Status Management)

- Real-time monitoring of equipment operating status and alarm messages, statistical analysis of operating status, alarm history, query and KPI.

- The equipment running status is divided into production, standby, shutdown and failure; these running information together with molding change information statistics and charts, managers can log in to the system to check equipment work situation in selected period, making comparison and analysis on the equipment running status for each month.

- Transparent equipment operation status, providing a basis for decision-making through the analysis and comparison of equipment operation status for the production, equipment and lean departments.

PQDM (Production and Quality Data Management)

- Management of production information for the tube mill line. In strip loading section, the steel strip information will be input into system by scanning gun or recipe recalling via touch screen. In the sawing section, the product yield information will be input.

- PIS system sends recipe to master control system, and the master control system assigns the recipe to the flying saw, then operator can write the recipe in advance according to the order. The product information will be entered into the system as the flying saw production completed.

- The packaging machine enters product information into the system, this product information is entered as a warehouse input product, meanwhile, the warehouse product output is recorded.

- The weigher enters the weight of the by-products (open-ended tubes, seamed tubes, short tubes) into the system.

- Monitor and analyze product history and quality data to realize product traceability and quality control and lay the foundation for data analysis.

EMS (Energy Management System)

- Collect energy consumption data at real-time to monitor all levels of water, electricity, gas/steam and other energy-consuming media on the equipment, production lines and workshops, realizing the transparency of energy consumption, which contributes to energy saving and emission reduction, optimizing energy-saving management.

- Real-time display of the operating status of each motor on the equipment such as running current, voltage, power, etc., These parameters could be check at any time, based on which the equipment can be judged whether to achieve peak performance.

Push Notifications on Dashboard & Mobile

Setup large screen to realize the dynamic real-time display of key production information such as KPIs, output and work orders, and also realize the active push display of key data through the rapid interaction of information through mobile terminals, so as to facilitate the production operators to find problems in time and solve problems quickly.

Value Highlights

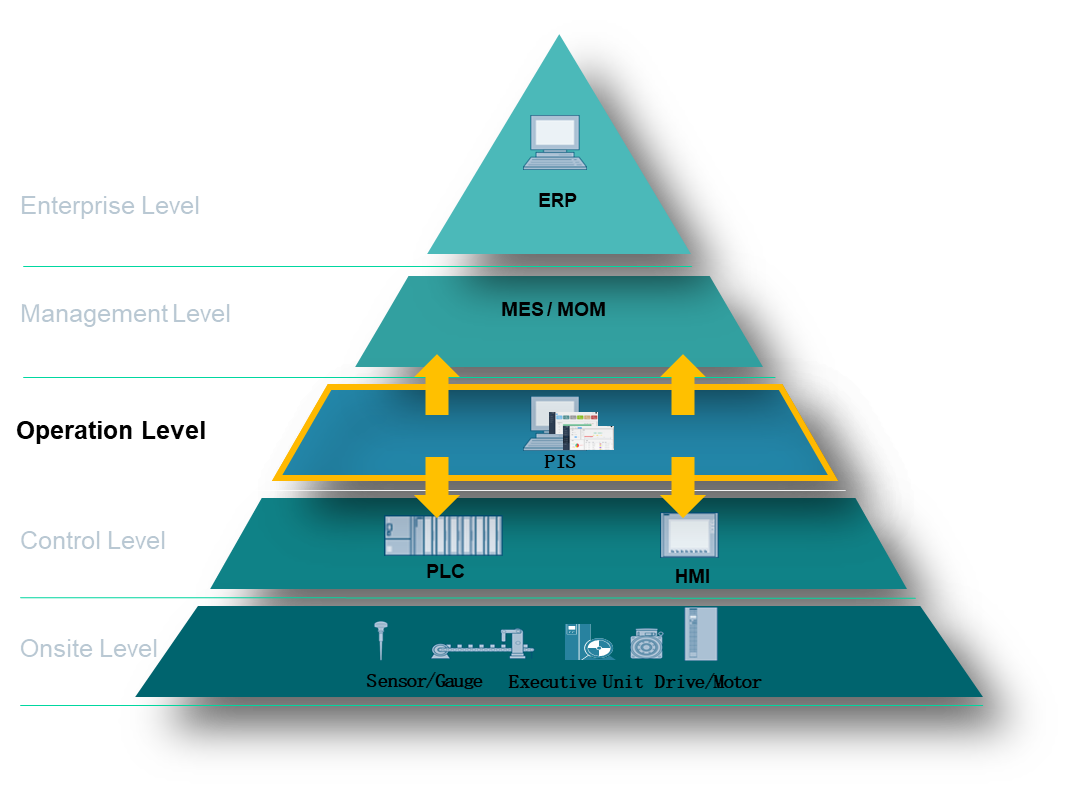

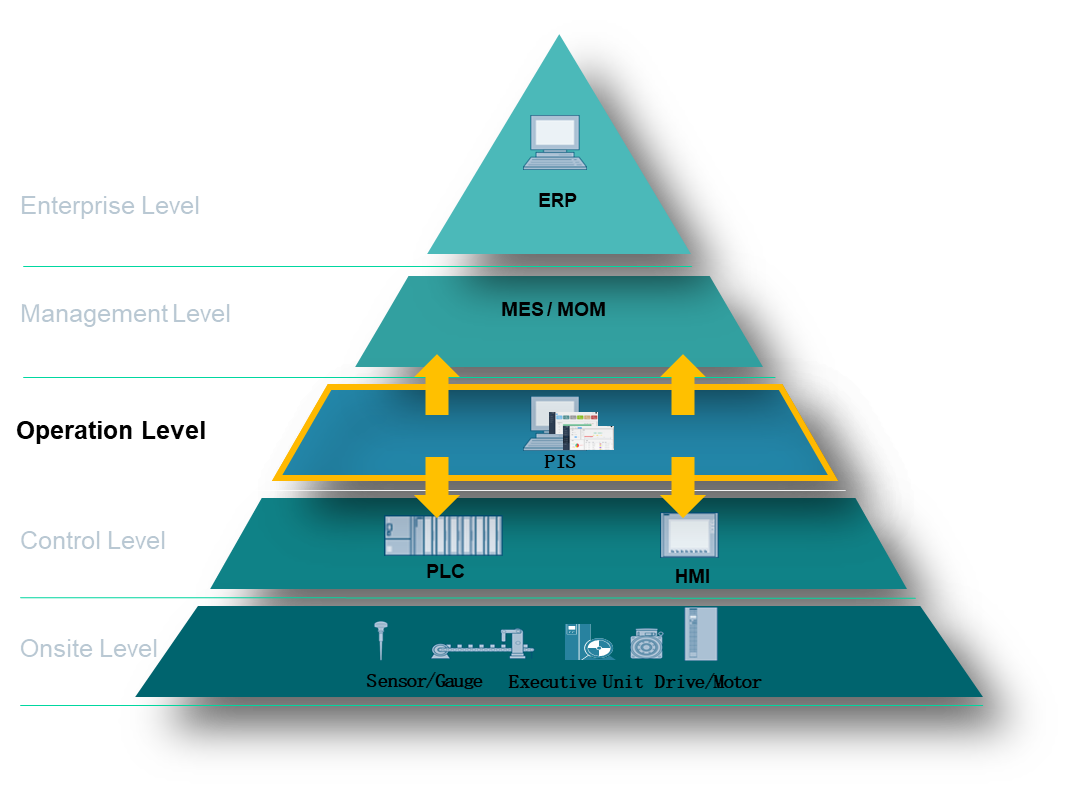

Intelligent Interconnection

This system is an integration of IT and OT, connecting OT devices at the automation layer including PLCs, drives, energy meters, etc., it can open the data to higher level management system of customers, helping to upgrade the digital intelligence of traditional production lines

Transparent Information

It is capable of capturing the production data of the whole ERW tube mill line process from coil loading, uncoiling, flying saw cutting to the final weighing and packaging section, to realize the transparency of the sawing production process, equipment operation status and energy consumption information.

Improvement of processes

With this intelligent production management and control system, we can realize the optimization of production plan and operation process, product recipe data management, and the sorting and optimization of production quality inspection process.

Enhancement of Cost-effectiveness

Improve management efficiency, improve equipment utilization efficiency, go paperless or less paper, improve the efficiency of issuing production orders, etc.