Our customers produce pipe & tubes, we supply the equipment and machinery.

SRET has developed the reliable & innovative technologies and offers a complete line of ERW pipe & tube mill machinery for almost any applications, from entry line, forming & sizing mill, welding machine, flying cut off units, to end finishing machines. SRET machines continue to increase the productivity and yield on more than a thousand of installations around the world and help our customers stay competitive in today’s business environment.

In addition to the standard machines, we also provides specialized equipment that covers a huge diameter range of tubes and pipes. SRET leadership in large diameter tube manufacturing technology is built upon innovations and uncompromising excellence in designing and manufacturing. Working with pipe & tube producers, SRET is working toward transforming leading-edge concepts into highly efficient pipe & tube making plants.

Simply put, SRET understands your business. That claim is backed by 30-years experience in ERW tube & pipe making industry. Leveraging our knowledge of your business and our upmost flexibility, SRET is able to create the most economical solutions, to help you drive sustainable cost reduction and competitive advantage while guaranteeing the latest technology and product quality.

Every pipe & tube mill line is unique! Experience from over thousands of successful cases worldwide, combined with the market’s most comprehensive offering, means that we can select the optimal and overall pipe & tube milling solution for your specific needs.

| Model No. | Size(mm) | Thickness(mm) | Speed(m/min) | HF Welder SiC (kw) |

| QX32 | ф10 – ф32 | 0.6 – 2.25 | 20 – 150 | 200 |

| □10 – □25 | ||||

| QX50 | ф12 – ф50 | 1.2 – 2.75 | 20 – 130 | 300 |

| □10 – □40 | ||||

| QX76 | ф32 – ф76 | 1.2 – 3.75 | 20 – 120 | 400 |

| □25 – □70 | ||||

| QX89 | ф32 – ф89 | 1.5 – 3.75 | 30 – 110 | 400 |

| □30 – □75 | ||||

| QX114 | ф40 – ф114 | 1.5 – 4.75 | 30 – 90 | 500 |

| □32 – □90 | ||||

| QX140 | ф48 – ф140 | 1.5 – 6.0 | 30 – 80 | 600 |

| □40 – □120 | ||||

| QX165 | ф76 – ф165 | 2.0 – 7.0 | 20 – 60 | 600 |

| □60 – □130 | ||||

| QX219 | ф89 – ф219 | 2.0 – 8.0 | 15 – 50 | 800 |

| □70 – □180 | ||||

| QX273 | ф114 – ф273 | 3.0 – 10.0 | 15 – 35 | 1000 |

| □89 – □200 | ||||

| QX325 | ф165 – ф325 | 5.0 – 12.7 | 10 – 30 | 1200 |

| □130 – □260 | ||||

| QX355 | ф165 – ф355 | 5.0 – 14.3 | 10 – 30 | 1200 |

| □130 – □280 | ||||

| QX406 | ф219 -ф406 | 6.0 – 16.0 | 10 – 30 | 1500 |

| □180 – □300 | ||||

| QX457 | ф219 – ф457 | 6.0 – 18.0 | 10 – 30 | 1500 |

| □180 – □360 | ||||

| QX508 | ф273 – ф508 | 6.0 – 20.0 | 10 – 25 | 1800 |

| □200 – □400 | ||||

| QX610 | ф273 – ф610 | 6.0 – 21.0 | 10 – 25 | 2100 |

| □200 – □480 | ||||

| QX660 | ф325 – ф660 | 6.0 – 22.0 | 10 – 25 | 2100 |

| □250 – □500 | ||||

| QX711 | ф325 – ф711 | 8.0 – 22.0 | 10 – 25 | 2400 |

| □250 – □600 |

| Model No. | Size(mm) | Thickness(mm) | Speed(m/min) | HF Welder SiC (kw) |

| QX – DFT120 | 60×60 – 120×120 60×80 – 100×120 | 1.8 – 6.0 | 20 – 60 | 600 |

| QX – DFT150 | 70×70 – 150×150 70×100 – 100×200 | 2.0 – 8.0 | 15 – 50 | 800 |

| QX – DFT200 | 80×80 – 200×200 80×100 – 150×200 | 3.0 – 10.0 | 15 – 35 | 1000 |

| QX – DFT250 | 100×100 – 250×250 100×150 – 200×250 | 5.0 – 14.0 | 10 – 30 | 1200 |

| QX – DFT300 | 120×120 – 300×300 120×160 – 250×300 | 5.0 – 15.0 | 10 – 30 | 1500 |

| QX – DFT400 | 180×180 – 400×400 180×220 – 300×400 | 6.0 – 16.0 | 10 – 30 | 1800 |

| QX – DFT500 | 250×250 – 500×500 250×300 – 400×500 | 6.0 – 18.0 | 10 – 30 | 2100 |

| QX – DFT600 | 300×300 – 600×600 300×400 – 500×600 | 6.0 – 20.0 | 10 – 25 | 2400 |

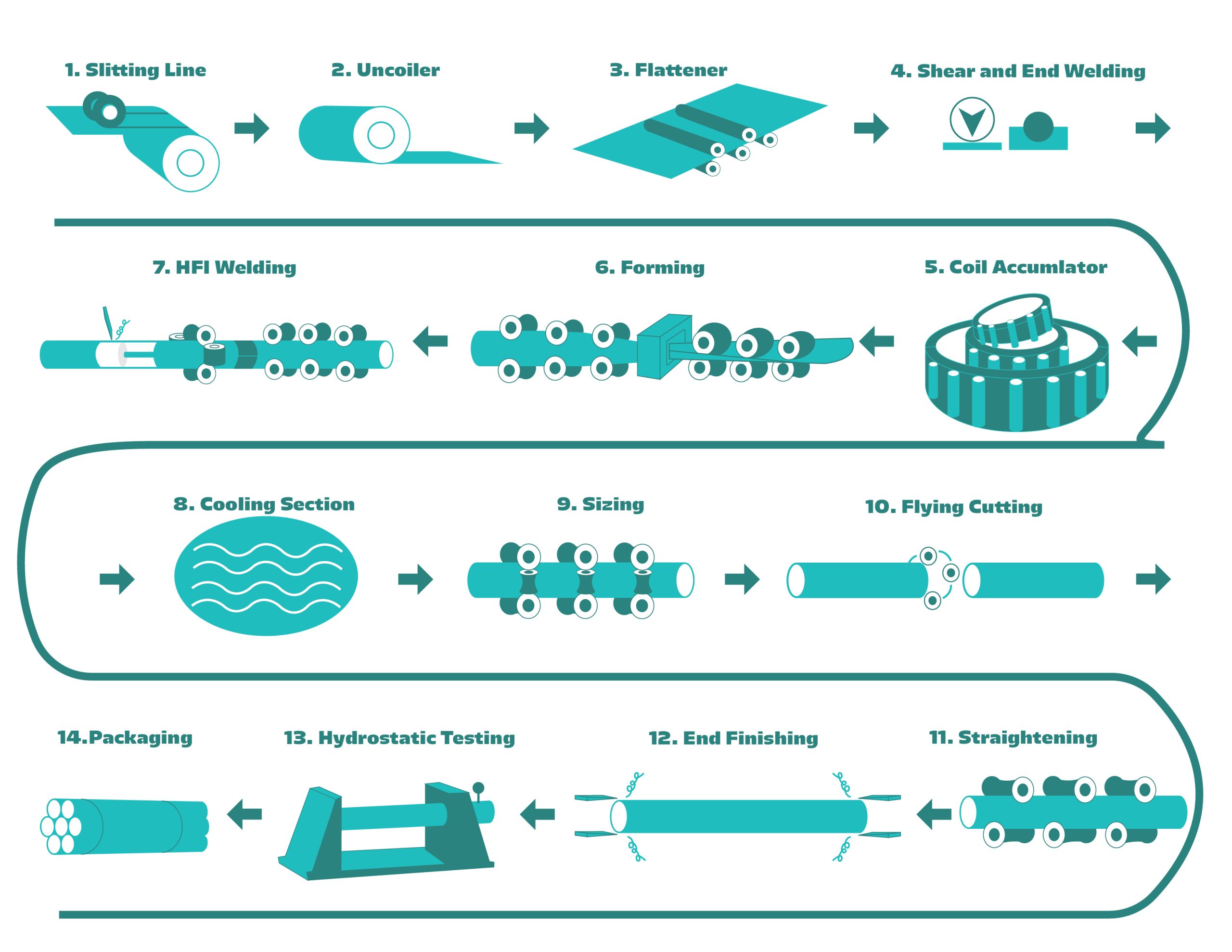

The Electric Resistance Welding ERW Tube Mill Line Machine is a critical piece of machine used inside the manufacturing of metal pipes and tubes. This business device plays a vital feature in generating splendid tubing for a big style of applications, beginning from structural purposes to transportation of fluids and gases. The ERW way is known for its performance, consistency, and functionality to meet the demands of modern corporations. The time period “ERW” refers in particular to the method of welding used, that’s based mostly on electric powered resistance and pressure to join the rims of rolled steel strips into tubular paperwork.

The production approach evolved with uncoiling and flattening metal strips from big rolls. These strips are then continuously fed into the ERW Tube Mill Line, in which they’ll be formed into round tubes the usage of forming rollers. As the strip passes thru the rollers, its edges are frequently delivered together. At the issue wherein the rims meet, immoderate-frequency electric powered present-day is done, which generates warmth due to the resistance of the steel. After welding, the tube passes via sizing and straightening sections to gain unique dimensions and uniformity. Finally, the tube is cut to the desired duration and might go through in addition finishing strategies, which incorporates deburring or inspection, earlier than being packaged for distribution.

One of the most massive blessings of the ERW Tube Mill Line Machine in China is its capability to offer tubes at excessive speeds, making it mainly efficient for huge-scale production. Additionally, the use of electric powered powered resistance welding eliminates the need for outside welding substances, decreasing standard production charges. The ensuing weld seam is regularly as sturdy due to the fact the lowest fabric, making ERW tubes suitable for disturbing packages. Another advantage is the ability of the ERW Tube Mill Machine Supplier in China. It can produce a large form of tube diameters and wall thicknesses via in truth changing the roller configurations and settings. This flexibility permits producers to cater to vital employer wishes without requiring separate machines for each duration or form.

ERW tubes are extensively applied in numerous sectors due to their sturdiness, uniformity, and fee-effectiveness. In the development industry, they are frequently used for scaffolding, structural facilitates, and fencing. In the car zone, they will be used for frames, exhaust systems, and distinct components. In the electricity enterprise, ERW tubes are employed for transporting oil, fuel, and water. Their use additionally extends to furnishings production, agriculture, and modern-day engineering packages. The consistency and electricity of ERW tubes make them appropriate for each pressure and non-pressure programs. In some instances, the tubes are galvanized or protected to decorate their corrosion resistance, similarly developing their usability in harsh environments.

Modern Enhancements in ERW Technology

With the improvement of the era, the current ERW Tube Mill Machine has seen large enhancements in automation, precision, and first-rate management. Computer-controlled systems permit for real-time monitoring of the welding method, ensuring consistent exceptional throughout huge manufacturing runs. Features on the side of automatic cloth feeding, digital length structures, and inline inspection devices have superior productivity and reduced waste. Moreover, enhancements in excessive-frequency welding technology have brought on better management over heat generation, resulting in purifier weld seams and reduced electricity consumption. As the call for better, best and greater fee-inexperienced manufacturing continues to upward thrust, the ERW Tube Mill stays at the forefront of metallic tube manufacturing.

Challenges and Maintenance

Despite its many advantages, the ERW Tube Mill Line isn’t always without worrying situations. Operators should frequently display the alignment of the rollers, the sharpness of the reducing blades, and the stability of the electric cutting-edge applied in welding. Misalignments or fluctuations in electric output can bring about horrible weld exceptional or dimensional inaccuracies. Regular protection is critical to preserve the gadget running successfully. This consists of lubrication of moving factors, cleansing of electrodes, and opportunity of worn components. Many manufacturers now put into impact predictive preservation systems the use of sensors and facts analytics to reduce downtime and growth device existence.

Environmental and Economic Considerations

From an environmental perspective, ERW Tube Mill Line Machine Manufacturer in China has several favorable attributes. The system generates a terrific deal of much less waste in evaluation to a few distinct welding techniques, and the capability to recycle steel in addition contributes to its sustainability. Additionally, the electricity overall performance of excessive-frequency welding reduces the general carbon footprint of manufacturing. Sret-Tech offers huge economic savings over extraordinary techniques, especially for large-scale production. The rate consistent with units is lower, and the velocity of manufacturing guarantees that supply can meet calls for immediate. This makes ERW Tube Mill Lines an appealing alternative for agencies aiming to balance brilliant with profitability.

ERW tubes are made through the manner of welding the edges of metallic strips together, at the same time as seamless tubes are made through a way of piercing a strong billet. Seamless tubes are normally used for excessive-pressure programs, however ERW Tube Mill are greater rate-powerful and sufficient for max structural and fluid delivery features.

In most instances, the weld seam in ERW Tube Mill Line Machine is minimum and may be removed or smoothed at some point of finishing. While it might be seen on near inspection, it no longer commonly has an effect on the electricity or common usual performance of the tube.

Carbon steel is the most unusual fabric applied in ERW tube generators, however stainless-steel and specific alloyed steels moreover may be processed, relying on the application and gadget skills.

Yes, ERW Tube Mill may be used for potable water if they may be nicely protected or galvanized and meet the health and safety requirements of the location in which they’re used.

With proper safety and regular servicing, an ERW Tube Mill Line Machine can last for several years. The lifespan is based upon at the operating situations, usage frequency, and amazing of the machine.