Our customers produce pipe & tubes, we supply the equipment and machinery.

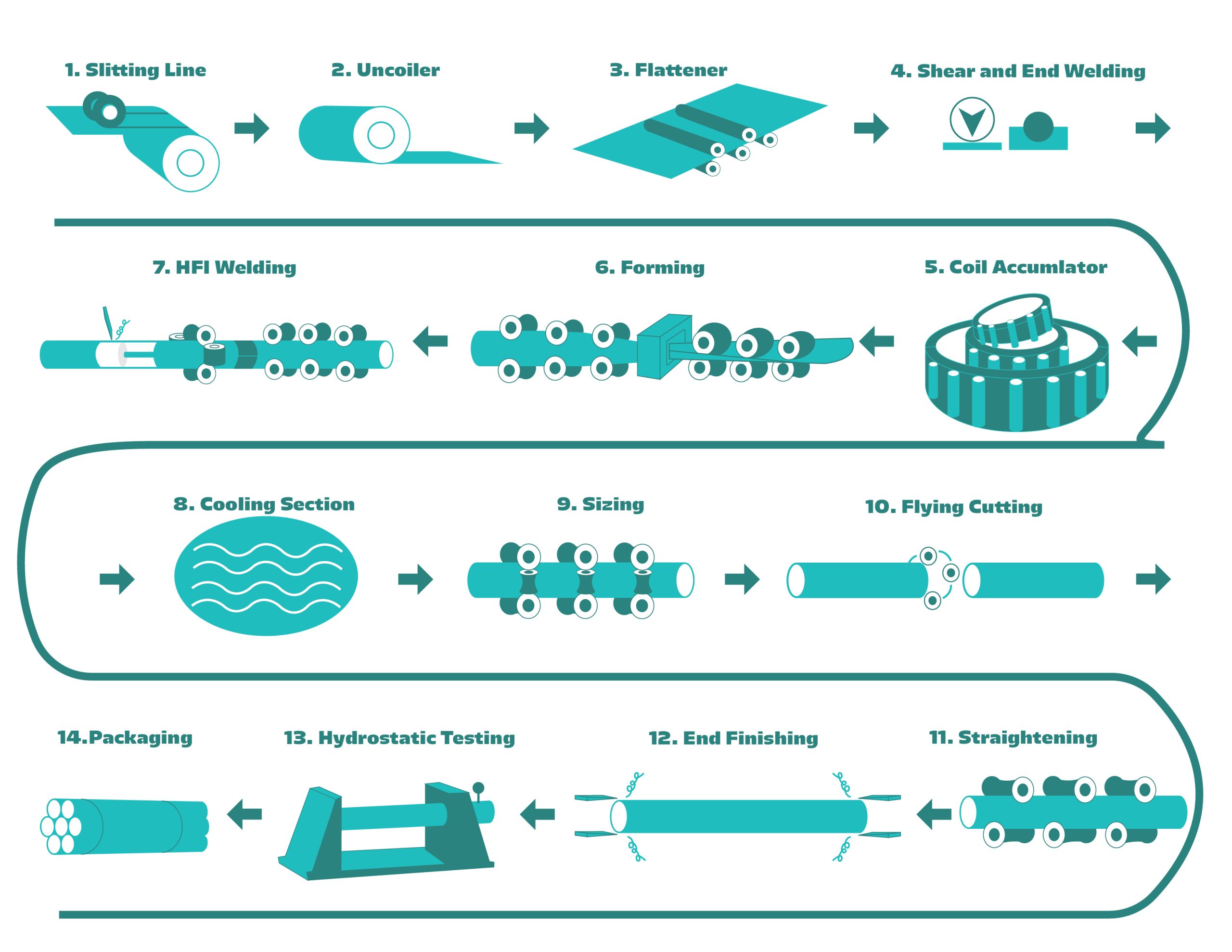

SRET has developed the reliable & innovative technologies and offers a complete line of ERW pipe & tube mill machinery for almost any applications, from entry line, forming & sizing mill, welding machine, flying cut off units, to end finishing machines. SRET machines continue to increase the productivity and yield on more than a thousand of installations around the world and help our customers stay competitive in today’s business environment.

In addition to the standard machines, we also provides specialized equipment that covers a huge diameter range of tubes and pipes. SRET leadership in large diameter tube manufacturing technology is built upon innovations and uncompromising excellence in designing and manufacturing. Working with pipe & tube producers, SRET is working toward transforming leading-edge concepts into highly efficient pipe & tube making plants.

Simply put, SRET understands your business. That claim is backed by 30-years experience in ERW tube & pipe making industry. Leveraging our knowledge of your business and our upmost flexibility, SRET is able to create the most economical solutions, to help you drive sustainable cost reduction and competitive advantage while guaranteeing the latest technology and product quality.

Every pipe & tube mill line is unique! Experience from over thousands of successful cases worldwide, combined with the market’s most comprehensive offering, means that we can select the optimal and overall pipe & tube milling solution for your specific needs.

Spec. | Size(mm) | Thickness(mm) | Speed(m/min) | HF Welder SiC (kw) |

Model | ||||

QX32 | ф10 – ф32 | 0.6 – 2.25 | 20 – 150 | 200 |

□10 – □25 | ||||

QX50 | ф12 – ф50 | 1.2 – 2.75 | 20 – 130 | 300 |

□10 – □40 | ||||

QX76 | ф32 – ф76 | 1.2 – 3.75 | 20 – 120 | 400 |

□25 – □70 | ||||

QX89 | ф32 – ф89 | 1.5 – 3.75 | 30 – 110 | 400 |

□30 – □75 | ||||

QX114 | ф40 – ф114 | 1.5 – 4.75 | 30 – 90 | 500 |

□32 – □90 | ||||

QX140 | ф48 – ф140 | 1.5 – 6.0 | 30 – 80 | 600 |

□40 – □120 | ||||

QX165 | ф76 – ф165 | 2.0 – 7.0 | 20 – 60 | 600 |

□60 – □130 | ||||

QX219 | ф89 – ф219 | 2.0 – 8.0 | 15 – 50 | 800 |

□70 – □180 | ||||

QX273 | ф114 – ф273 | 3.0 – 10.0 | 15 – 35 | 1000 |

□89 – □200 | ||||

QX325 | ф165 – ф325 | 5.0 – 12.7 | 10 – 30 | 1200 |

□130 – □260 | ||||

QX355 | ф165 – ф355 | 5.0 – 14.3 | 10 – 30 | 1200 |

□130 – □280 | ||||

QX406 | ф219 -ф406 | 6.0 – 16.0 | 10 – 30 | 1500 |

□180 – □300 | ||||

QX457 | ф219 – ф457 | 6.0 – 18.0 | 10 – 30 | 1500 |

□180 – □360 | ||||

QX508 | ф273 – ф508 | 6.0 – 20.0 | 10 – 25 | 1800 |

□200 – □400 | ||||

QX610 | ф273 – ф610 | 6.0 – 21.0 | 10 – 25 | 2100 |

□200 – □480 | ||||

QX660 | ф325 – ф660 | 6.0 – 22.0 | 10 – 25 | 2100 |

□250 – □500 | ||||

QX711 | ф325 – ф711 | 8.0 – 22.0 | 10 – 25 | 2400 |

□250 – □600 |

Spec. | Size(mm) | Thickness(mm) | Speed(m/min) | HF Welder SiC (kw) |

Model | ||||

QX – DFT120 | 60×60 – 120x12060x80 – 100×120 | 1.8 – 6.0 | 20 – 60 | 600 |

QX – DFT150 | 70×70 – 150×150 70×100 – 100×200 | 2.0 – 8.0 | 15 – 50 | 800 |

QX – DFT200 | 80×80 – 200×200 80×100 – 150×200 | 3.0 – 10.0 | 15 – 35 | 1000 |

QX – DFT250 | 100×100 – 250×250 100×150 – 200×250 | 5.0 – 14.0 | 10 – 30 | 1200 |

QX – DFT300 | 120×120 – 300×300 120×160 – 250×300 | 5.0 – 15.0 | 10 – 30 | 1500 |

QX – DFT400 | 180×180 – 400×400 180×220 – 300×400 | 6.0 – 16.0 | 10 – 30 | 1800 |

QX – DFT500 | 250×250 – 500×500 250×300 – 400×500 | 6.0 – 18.0 | 10 – 30 | 2100 |

QX – DFT600 | 300×300 – 600×600 300×400 – 500×600 | 6.0 – 20.0 | 10 – 25 | 2400 |