An ERW tube mill is crucial for producing strong, durable steel pipes through electric resistance welding. This article covers how ERW tube mills work, their benefits, and top machines and manufacturers in the field.

Electric Resistance Welded (ERW) tube mills are indispensable in producing high-quality steel pipes. These mills utilize electric resistance welding, a method that joins steel edges using an electric current to create robust and durable welded tubes. ERW tubes are renowned for their strength, durability, and versatility, making them suitable for various applications. The process involves transforming flat steel strips into cylindrical shapes, ensuring precision and high-quality outputs essential for numerous industries. erw pipe mills play a crucial role in this production process.

China dominates the global production of ERW tube mills, accounting for over 63% of the market. This dominance highlights the widespread adoption and reliance on ERW technology for steel pipe production. Companies like Alliance Tubular Products leverage this technology to manufacture a diverse range of tubing, showcasing the flexibility and efficiency of ERW tube mills.

Electric resistance welding (ERW) is at the heart of the ERW tube mill process, playing a pivotal role in producing strong, durable steel pipes. This welding method involves heated edges of steel strips and applying pressure to fuse them into a tube using high-frequency electrical currents. This process guarantees a strong weld seam, vital for the structural integrity of the final product. Companies like Lotos Forming utilize high-frequency welding technology to enhance the welding process, ensuring that the final steel pipes meet industry standards.

The precision and reliability of electric resistance welding are crucial for producing high-quality welded tubes. This method not only guarantees a strong weld but also ensures that the pipes can withstand various pressures and applications. High-frequency electrical currents allow ERW tube mills to produce pipes with consistent wall thickness, enhancing durability and performance.

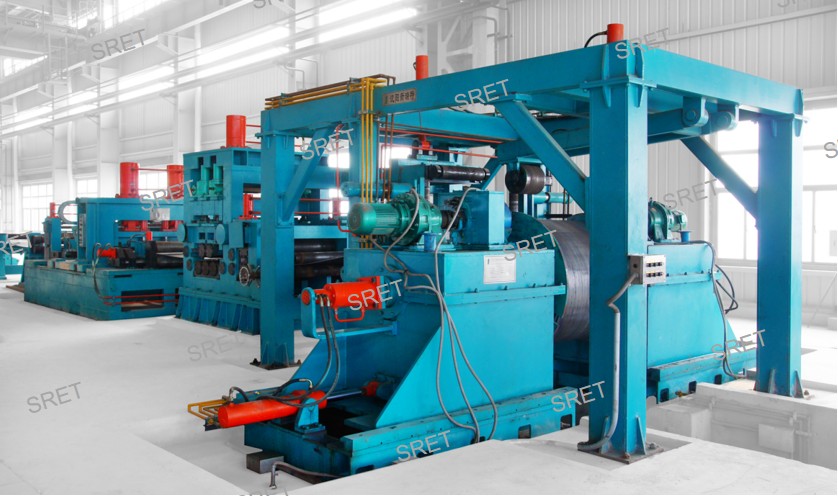

An ERW tube mill comprises several key components that work in harmony to produce high-quality steel pipes:

The vertical accumulator plays a crucial role by storing steel strips, ensuring uninterrupted operation during the welding process. The Double Cone Decoiler supports the coil and supplies raw materials for the welding section, maintaining strip tension with a pneumatic brake system.

The horizontal accumulator further stabilizes the feeding process, reducing bending and noise during welding. These components collectively contribute to the efficiency and precision of the ERW tube mill production process.

The production process of ERW tubes is a marvel of modern engineering, combining efficiency with precision. It involves:

Top Tubes, a notable player in the industry, exemplifies this efficiency-driven and precision-focused transformation of cold-formed steel strips into high-quality ERW tubes. The production process is designed to minimize delays and maximize output rates, ensuring that the final product is a high-quality steel pipe suitable for various industries.

The journey from a flat strip steel strip to a cylindrical pipe involves several stages:

This stage is critical as it ensures that the steel strip is accurately formed and prepared for the subsequent welding process. The precision in forming the steel strip into a cylindrical shape ensures that the final ERW tube meets the required specifications and standards.

High-frequency welding is a cornerstone of the ERW tube production process. This method uses induction heating to bond the edges of the steel strip, resulting in a strong and durable weld seam. Modern advancements in ERW technology, such as the transition to High-Frequency Welding (HFW), have further enhanced weld integrity and overall pipe performance. The application of high-frequency electrical resistance ensures that the steel strip edges are effectively welded together.

After high-frequency welding, any burrs outside the weld seam are typically removed to ensure a smooth finish. This precision in the welding process allows ERW tube mills to produce tubes with tight tolerances, increasing material yield and reducing waste.

Post-welding, the pipes undergo the following steps:

The pipes are then cut to the required lengths for distribution and use in various applications. This final step ensures that the pipes are prepared for their intended use, maintaining the high standards expected from ERW tube mills.

ERW tube mills offer several advantages that make them the preferred choice for producing steel pipes:

Manufacturers like Lotos Forming have capitalized on the high-speed production capabilities of ERW tube mills, offering low material waste and flexibility for various diameters and thicknesses. These advantages make ERW tube mills a reliable and efficient solution for producing high-quality steel pipes.

One of the standout features of ERW tube mills is their high production efficiency and speed. For example, the ERW 76 Tube Pipe Mill Line achieves a maximum line speed of 120m/min, significantly boosting production rates. Technologies like FFX forming improve the quality of welded pipes by stabilizing the forming process and reducing defects through continuous bending methods.

Automated ERW tube mills have dramatically improved production efficiency and reduced lead times for various manufacturers. Aligning the mill’s output capability with market demand is vital to avoid overproduction or supply shortages, ensuring that high-speed production translates to operational efficiency and production speed.

The cost-effectiveness of ERW tube mills is another significant advantage. The manufacturing process involves low raw material costs, contributing to overall cost-effectiveness. Investing in high-quality tube mills can lead to significant long-term savings by minimizing maintenance needs and increasing operational efficiency.

Modern ERW mills now employ AI-driven thickness control systems that significantly reduce material waste by approximately 22%. A Middle Eastern energy company reported a 40% decrease in operational costs after upgrading to a new Chinese ERW mill with integrated automatic gauge control.

ERW tubes are versatile and can be tailored to meet specific requirements for different applications across multiple sectors. They are commonly utilized across diverse sectors such as construction, automotive, and oil and gas due to their flexibility.

The ability to produce ERW tubes in a variety of sizes and wall thicknesses makes them adaptable to specific project requirements. This versatility ensures that ERW tube mills can cater to the needs of various industries, enhancing their overall productivity and profitability.

When selecting an ERW tube mill, it’s crucial to consider several factors to ensure the chosen equipment meets your specific needs. Aligning the mill’s production capacity with your demand is essential to maintain efficiency and avoid overproduction or supply shortages. Additionally, the quality and durability of the equipment are vital for long-term reliability and performance.

Customization and flexibility are also important considerations. Opting for an ERW tube mill that offers full customization options can enhance a manufacturer’s ability to meet specific production requirements and adapt to varying market needs.

Aligning the production capacity of an ERW tube mill with market demand is vital for efficiency. ERW tube mills have varying capacities depending on the specific model and configuration, affecting production output levels. Implementing flexible production schedules can help meet fluctuating demand, optimizing resource usage.

Customizable ERW tube mills enhance a manufacturer’s agility in responding to market dynamics and customer needs. This flexibility ensures that the production process remains efficient and aligned with market requirements.

Investing in machines with robust engineering and high-quality materials is essential for long-term reliability. Leading manufacturers in the ERW tube mill sector emphasize quality control, offering advanced technology and support for high-efficiency production.

Choosing durable equipment ensures that the ERW tube mill can withstand the rigors of continuous operation, minimizing downtime and maintenance costs. This focus on quality and durability ultimately contributes to the overall productivity and cost-effectiveness of the production process.

Customization options in ERW tube mills enable manufacturers to meet specific production requirements and adapt to varying market needs. Full customization options are available to meet specific requirements for Lotos Forming’s ERW tube mills, ensuring that the equipment aligns perfectly with the manufacturer’s goals.

This flexibility in customization ensures that manufacturers can produce a wide range of pipe sizes and specifications, catering to diverse industry demands. The ability to customize the equipment enhances the overall efficiency and productivity of the ERW tube mill.

Reliable ERW tube mill manufacturers are crucial for enhancing productivity and quality in steel pipe production. Top manufacturers are recognized for their advanced machinery and reliable production capabilities, offering robust service and support to ensure continued efficiency and minimal downtime.

Many notable manufacturers provide customizable features to meet specific client needs, enhancing versatility in production. These manufacturers play a vital role in driving innovation and maintaining high standards in the ERW tube mill industry.

Advancements in ERW tube mill technology have significantly enhanced the efficiency and adaptability of these machines through:

Recent innovations include fully automated direct form lines, improving the speed and consistency of production. Upgrades to control systems enhance reliability and precision, ensuring that the final product is capable of meeting high-quality standards consistently and is fixed in its performance, regardless of length.

Real-world implementations of ERW tube mills provide valuable insights into their effectiveness and impact on production capabilities. Top Tubes, for instance, has achieved a production rate of up to 1000 tonnes per week by implementing advanced ERW tube mill technology. This significant increase in production rate has not only enhanced their market competitiveness but also improved profitability.

These case studies show how investing in state-of-the-art ERW tube mills can lead to substantial productivity gains and operational efficiencies. By leveraging advanced technology and robust machinery, manufacturers can meet the growing demand for high-quality steel pipes while maintaining cost-effectiveness and efficiency.

In summary, ERW tube mills play a crucial role in the modern production of high-quality steel pipes. The electric resistance welding process ensures strong and durable welded tubes, while the advanced components and automated systems contribute to high production efficiency and precision. The advantages of using ERW tube mills, such as cost-effectiveness, material optimization, and versatility for various industries, make them an indispensable asset for manufacturers.

As we have seen, leading manufacturers continue to innovate, incorporating advanced technologies and customization options to meet specific market demands. Real-world case studies further underscore the impact of these innovations on production capabilities and market competitiveness. Investing in high-quality ERW tube mills is a strategic decision that can drive significant long-term benefits, ensuring manufacturers remain at the forefront of the steel pipe production industry.

The primary method used in ERW tube mills to weld steel pipes is electric resistance welding, where high-frequency electrical currents heat the edges of steel strips, and pressure is applied to fuse them into a tube.

The key components of an ERW tube mill are the forming machine, vertical accumulator, Double Cone Decoiler, and horizontal accumulator, which collaborate to facilitate efficient and precise steel pipe production.

High-frequency welding significantly enhances the quality of ERW tubes by employing induction heating for robust edge bonding, ensuring a strong and durable weld seam. This method also guarantees tight tolerances while minimizing material waste.

ERW tube mills provide high production efficiency, speed, cost-effectiveness, and versatility across various industries. These advantages make them an optimal choice for manufacturers seeking reliable and high-quality steel pipe solutions.

It is essential to match an ERW tube mill’s production capacity to market demand to maintain operational efficiency and minimize the risks of overproduction or shortages. This alignment enables manufacturers to effectively meet market requirements while optimizing resources.