An ERW tube mill factory specializes in producing high-quality steel pipes using state-of-the-art electric resistance welding technology. These factories are crucial for industries that demand strong and precise steel pipes. In this article, we’ll delve into how ERW tube mill factories operate, their essential components, the production process, and the key benefits they offer across industries.

An ERW tube mill factory is a marvel of modern engineering, utilizing high-frequency welding technology to produce robust steel pipes. These mills are designed to meet the growing demand for high-quality steel pipes across various industries. Understanding the basic structure and functionality of an ERW tube mill factory is fundamental before discussing specifics. Key factors to consider include:

The core of these factories lies in their ability to transform steel strips into precision-engineered pipes. The process begins with feeding steel strips into the production line, where they are formed and welded into pipes. This method not only ensures consistent quality but also enhances production efficiency, making ERW tube mills a preferred choice for producing steel pipes.

Several critical components work in unison at the heart of every ERW tube mill factory to produce high-quality steel pipes. Uncoilers play a pivotal role by feeding a coil of steel into the production line, initiating the process of tube formation. These coils of steel strips are the raw materials that undergo a series of transformations to become finished pipes.

Welding units are another vital component. They utilize electric current to fuse the metal edges, ensuring strong and consistent seams. Taoguan Technology, for instance, specializes in designing and producing a wide range of tube mill machines, including high-frequency longitudinal welded pipe units, which are integral to the functioning of these factories. Electric resistance welding is a key process in achieving these strong seams.

These components together form a seamless production line that guarantees efficiency and precision in producing steel pipes using a pipe making machine.

The production process in an ERW tube mill factory is a fascinating blend of technology and precision. It all begins with high-frequency welding, the primary method used in the ERW tube mill production line. This technique involves heating the steel strips to a high temperature and then welding them together to form a pipe. The result is a seamless and strong welded pipe that meets stringent industry standards.

A critical aspect of this process is the ability to change pipe sizes using the fixed and replaceable tooling method. Although this method requires manual removal of old forming rolls and installation of new ones, it allows for the production of various sizes and types of pipes. However, it’s worth noting that this method can be time-consuming and requires a complete shutdown of the production line.

Exploring the advantages of ERW tube mills is the next step after understanding the production process. These mills offer numerous benefits that make them a preferred choice in the industry, from cost-effective production to high production speed and versatility in pipe production.

ERW tube mills have carved a niche for themselves in the industrial manufacture landscape. Producing high-quality steel pipes with remarkable efficiency has made them widely indispensable.

But what exactly makes them so advantageous? The following sections delve into the cost-effective production, high production speed, and versatility that ERW tube mills offer.

One of the standout features of ERW tube mills is their cost-effectiveness. The automated manufacturing processes employed in these mills significantly lower labor costs, making the production of steel pipes more economical. The quick turnaround times and shortened production cycles enhance efficiency, allowing for a higher output of finished products.

Advanced control systems, including PLC and HMI, play a crucial role in optimizing production operation. These systems ensure that the production process is capable of running smoothly and efficiently, contributing to the overall cost-effectiveness of ERW tube mills.

Companies like LotosForming are noted for providing cost-effective and high-quality pipe manufacturing solutions that fill a supplier sale need, making them key players in the global market.

In today’s fast-paced industrial environment, the ability to produce large quantities of steel pipes quickly is a significant advantage. ERW tube mills excel in this area, optimizing production efficiency through high production speed with minimal line downtime. This capability is crucial for meeting industry demands and staying competitive in the market.

Minimizing line downtime maximizes production output, enabling manufacturers to respond promptly to market needs and order fulfillment. The high production speed of ERW tube mills allows for rapid manufacturing of steel pipes at a low production cost, setting leading mills apart from their competitors.

Versatility is another hallmark of ERW tube mills. These mills can efficiently produce various sizes, shapes, and wall thicknesses of steel pipes, catering to the specific needs of different industrial applications. This adaptability is achieved by simply changing molds, allowing for the production of pipes with varied specifications.

The process begins with a steel coil, which is formed into a cylindrical shape before the edges are welded together. This method supports the creation of pipes in various wall thicknesses, ranging from 0.70mm to 3.20mm, making ERW tube mills suitable for producing round pipes for diverse projects.

Quality is paramount in the production of steel pipes, and ERW tube mills are no exception. Ensuring a high degree of quality output involves rigorous quality control processes and the use of advanced technology.

The following sections explore these aspects in detail, highlighting the measures taken to maintain product quality standards, ensuring precision.

Quality control in ERW tube mills begins with the strict testing of raw materials to ensure they meet required mechanical and chemical standards. Continuous monitoring of welding parameters such as current and speed is essential for maintaining consistent weld quality during production. This ensures that the pipes produced are structurally sound and free of defects.

Post-manufacturing inspections verify dimensional accuracy and wall thickness, ensuring the structural integrity of the pipes. Non-destructive testing methods like ultrasonic and eddy current testing are also employed to identify defects in finished pipes, further ensuring the quality and reliability of the final product.

Modern ERW tube mills employ automation technologies to enhance precision and efficiency throughout the manufacturing process. Automation allows for enhanced precision during production processes, significantly lowering energy consumption and contributing to overall cost savings in production.

Global leaders in the ERW tube mill industry emphasize innovation and quality in their manufacturing processes, ensuring that the products they produce meet the highest standards of excellence. This commitment to advanced technology and quality assurance sets leading ERW tube mills apart from their competitors.

ERW tube mills provide tailored solutions for a wide range of industries, from automotive to construction and oil and gas. These mills play a crucial role in supporting diverse applications by producing steel pipes that meet specific industry requirements.

The following sections explore the applications of ERW tubes in various industries.

In the automotive industry, ERW tubes are used for creating lightweight structural components that enhance fuel efficiency. These tubes provide essential support and load-bearing capacity, making them integral to vehicle manufacturing.

The use of ERW tubes in vehicles highlights their versatility and importance in the industry.

The construction industry relies heavily on ERW tubes for their strength and durability. These structural tubes are used in structural applications such as beams and columns, providing the necessary support for building projects.

Welded steel pipes produced by a pipe mill and tube mills are also key for scaffolding, plumbing systems, and structural supports in construction. Steel pipe is essential in these applications.

The oil and gas industry benefits from the cost-effectiveness and durability of ERW tube production. These tubes are designed to handle the corrosive nature of substances in oil and gas pipelines, ensuring longevity and safety.

Their strong structural integrity makes them critical for transporting fluids under high pressure.

Effective after-sales service and support are crucial for maintaining reliable customer satisfaction and ensuring the long-term functionality of ERW tube mills.

The following sections detail the maintenance and technical support services provided to customers.

Regular maintenance of ERW tube mills is essential to prevent breakdowns and ensure smooth operations. Maintenance services are crucial for ensuring the longevity and efficiency of the equipment, contributing to its overall reliability.

Ongoing maintenance support ensures that tube mill equipment remains in optimal condition, allowing for continuous and efficient production on the tube mill line. This proactive approach to maintenance helps in minimizing downtime and maximizing productivity.

Technical support is readily available to assist customers with troubleshooting and operational inquiries related to ERW tube mills. This support ensures that any issues or concerns are promptly addressed, enhancing the overall customer experience. For further assistance, customers can contact us.

Professional after-sales support is provided to ensure that customer inquiries and issues are handled efficiently, fostering trust and satisfaction among customers. This commitment to customer support sets leading ERW tube mill manufacturers apart from their competitors.

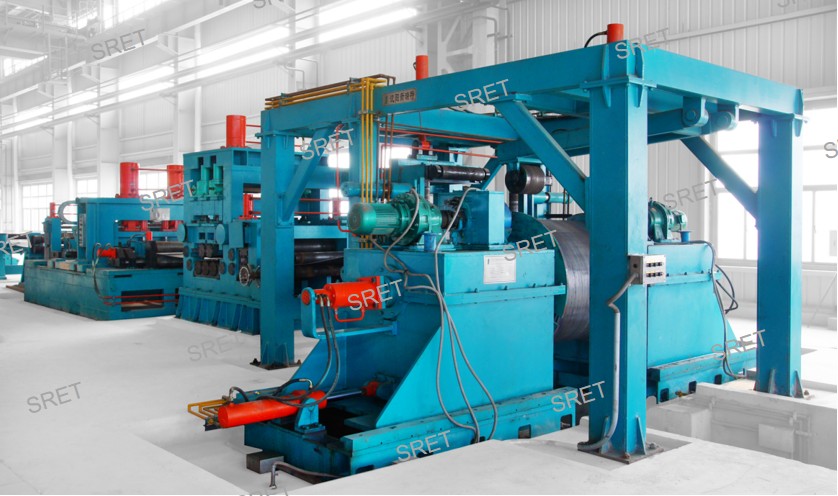

SRET Co., Ltd. stands as a leading ERW tube mill factory in China, with a rich history and a commitment to innovation and quality. Founded in Shenyang, Liaoning province, in 1989 by five university senior professors, SRET has been a pioneer in China’s tube mill machine manufacturing industry.

Over the past three decades, SRET has remained at the forefront of the industry, continuously innovating and improving the quality of its products. The company designs, engineers, manufactures, and supplies a full range of ERW tube mill machinery that meets the diverse needs of its customers.

SRET’s highly qualified engineering team and experienced production team ensure that the equipment delivered to customers is of the highest quality, promising top performance and the production of high-grade tubes. This dedication to excellence has distinguished SRET from its competitors and established it as a leader in the ERW tube mill industry.

ERW tube mills have revolutionized the production of steel pipes, offering numerous advantages such as cost-effectiveness, high production speed, and versatility. By employing advanced technology and rigorous quality control processes, these mills ensure the production of high-quality steel pipes that meet the demands of various industries.

From automotive to construction and oil and gas, ERW tubes play a critical role in supporting diverse applications. Leading manufacturers like SRET Co., Ltd. exemplify the commitment to innovation and quality that drives the industry forward. As we look to the future, the continued evolution of ERW tube mills promises even greater efficiency and reliability in pipe production.

An ERW tube mill produces steel pipes through high-frequency welding technology, ensuring consistent quality and efficient manufacturing. This process is essential for creating durable and reliable tubing.

The key components of an ERW tube mill factory include uncoilers that supply steel coils and welding units that fuse the metal edges to create pipes. These elements are essential for efficient production.

An ERW tube mill ensures product quality through continuous monitoring of welding parameters, post-manufacturing inspections, and the application of non-destructive testing methods to detect defects. This rigorous quality control approach is essential for maintaining high standards in production.

ERW tube mills significantly benefit industries such as automotive, construction, and oil and gas by delivering customized solutions to meet their specific needs.

After-sales support for ERW tube mills includes regular maintenance services and technical assistance to maintain the equipment’s long-term functionality and efficiency. This ongoing support is crucial for optimal performance and reliability.