Finding a reliable ERW tube mill manufacturer from China is crucial for your business. In this guide, we’ll show you how to choose a reliable ERW tube mill manufacturer from China by evaluating their reputation, production capacity, quality assurance, and more to ensure you make the right choice.

The manufacturer’s reputation is a vital indicator of their reliability and the quality of their products. When evaluating tube mill manufacturers, considering their market presence and customer feedback is crucial. Manufacturers with a strong market presence are generally more stable and reliable, which is crucial for long-term partnerships.

Customer reviews and industry references are invaluable resources for gauging the trustworthiness of erw tube mill manufacturers. A proven track record of positive customer experiences and successful projects can significantly boost a manufacturer’s reputation. The longevity of a manufacturer in the industry often reflects their commitment to product quality and customer satisfaction. Additionally, the reliability of erw tube mills plays a crucial role in maintaining high standards. Furthermore, connecting with erw tube mill suppliers can enhance access to quality products.

It’s also beneficial to consider the manufacturer’s past projects to assess their ability to deliver on promises. A manufacturer with a history of high-quality projects is more likely to provide consistent product quality and effective quality control measures. Focusing on these aspects helps identify reputable manufacturers who are likely to meet your expectations.

Understanding a manufacturer’s production capacity and output capacity is crucial for ensuring they can meet your production requirements. Production capacity refers to the maximum output a factory can achieve within a specific timeframe. Aligning this production volume with market demand helps avoid delays and optimize resource use.

Evaluating the technical deep expertise of a manufacturer is equally important alongside production capacity. This encompasses their ability to manage complex manufacturing processes and produce various pipe diameters and wall thicknesses. Companies like Baolai Steel Group, known for their large-scale production capabilities, exemplify the importance of technical resources and guidance on material selection to ensure product quality.

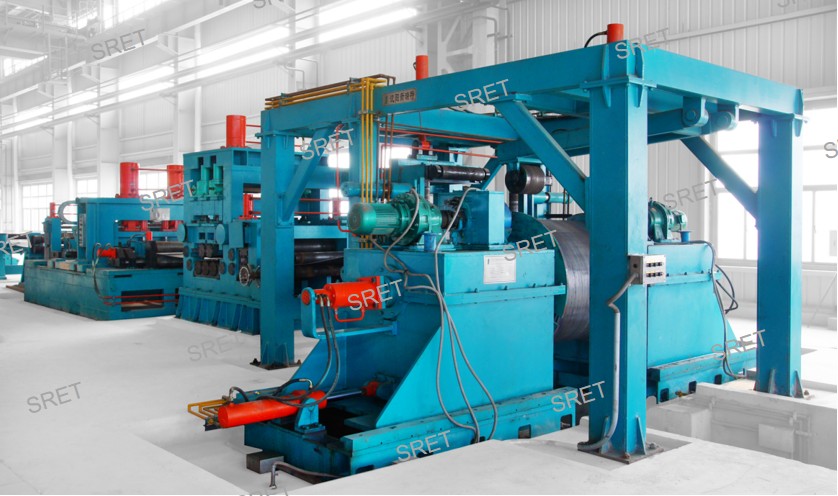

Advanced automation and precision engineering are key factors in enhancing production efficiency in industrial manufacturing. Chinese pipe mill manufacturers have adopted these technologies to improve operational efficiency and production speed. Considering these factors ensures that the manufacturer has the necessary technical expertise and production capacity to meet your needs in the production process involving steel pipe.

Quality assurance is a cornerstone of reliable manufacturing. Reputable manufacturers implement rigorous quality control measures to ensure consistent product quality and build quality. For instance, Chinese pipe mills commonly hold the EN 10204 3.1 certification, ensuring traceability and high standards. Certifications like ISO 9001, held by Metal Zenith, reflect a strong commitment to quality management practices.

Requesting Mill Test Certificates, Hydrostatic Test Certificates, and Non-Destructive Test reports further ensures product quality. These documents verify that the products meet the necessary specifications and standards. Compliance with international standards such as ASME B36.10M and ASTM is also crucial for maintaining consistent quality and ensuring that the products meet global benchmarks.

Chinese ERW tubes have demonstrated their capability to adhere to high-quality benchmarks in international projects, such as the Jakarta-Bandung HSR project. Focusing on quality assurance, structural integrity, and certifications ensures that the manufacturer provides consistent and reliable products that meet your standards.

Advanced technology and innovation play a critical role in the tube manufacturing process. Technologies such as HAZControl™ allow for precise control of heat input during high-frequency welding, enhancing the quality and efficiency of producing tubes and welded tubes. The Thermatool AutoMatch™ feature automatically adjusts welding parameters to ensure optimal power output across various product sizes, showcasing the importance of high frequency induction welding technology in modern manufacturing.

Automated control systems and predictive algorithms further enhance the efficiency of the manufacturing process. These systems enable operators to tailor weld parameters efficiently, reducing waste and improving product quality. Leveraging advanced technology allows manufacturers to produce high-quality tubes with consistent welds, enhancing overall product quality and operational efficiency in the welding process.

Opting for a manufacturer that prioritizes innovation and employs advanced technology guarantees high quality materials products that meet your product specifications. This emphasis on technology and innovation results in positive feedback, valuable insights, technical support, and optimal performance, enhancing your overall experience and satisfaction.

Conducting a thorough cost analysis is crucial when selecting an ERW tube mill manufacturer. The initial purchase price of an ERW pipe mill can vary significantly based on its size, capabilities, and features. Installation costs, including site preparation and electrical work, should also be factored into the overall investment. Additionally, exploring various erw tube mill options can help in making a more informed decision.

A comprehensive total cost analysis should consider factors such as transportation, potential delay costs, and the risk of poor materials. Evaluating cost efficiency from modern ERW technology can reduce waste, contributing to cost savings in raw materials. Understanding the depreciation rates of the equipment is vital for accurate financial planning and tax considerations.

Calculating the return on investment involves estimating net profits from increased production and improved quality against the initial investment cost. High-frequency ERW mills, for instance, can lead to greater production efficiency, enhancing profitability and market competitiveness. Balancing costs and evaluating the long-term value helps make an informed decision that ensures a positive return on investment.

After-sales support and maintenance services are critical for the long-term performance of your tube mills. Regular maintenance is crucial for peak efficiency, influencing both ongoing costs and the longevity of the equipment. Manufacturers should provide clear guidelines for routine maintenance to prolong equipment life.

Effective spare parts management is also crucial for minimizing downtime and ensuring continuous production. Strategic spare parts management aims to minimize inventory while ensuring that critical components are readily available, achieving a balance that enhances operational reliability. Vendor Managed Inventory (VMI) systems, where suppliers hold stock on-site and manage replenishment based on actual usage, can further improve availability and reduce capital tied up in inventory.

Key factors to enhance the performance and reliability of your tube mills and tube mill machine include:

Spare parts availability is a critical factor in minimizing downtime and ensuring continuous production. Effective after-sales support includes prompt response times and comprehensive service options. Clear classification of parts and determining which items are essential for continuous production are key aspects of effective spare parts management to minimize downtime.

Ineffective management of spare parts can lead to production halts and significant financial losses. Ensuring that the manufacturer provides readily available spare parts and robust inventory processes minimizes downtime and maintains optimal production capacity.

Energy efficiency and environmental compliance are increasingly important in the manufacturing industry. High-frequency electric resistance welded pipe mills are more energy-efficient compared to older models, affecting long-term operating expenses. The design of products, including components like insulation and materials, plays a critical role in enhancing their energy efficiency.

Sustainable energy practices focus on reducing energy consumption and promoting energy-efficient designs to minimize environmental impact. Manufacturers are increasingly adopting renewable energy sources like solar and wind to replace fossil fuels, thereby lowering their environmental impact. Setting carbon footprint reduction goals helps manufacturers manage greenhouse gas emissions throughout a product’s life cycle, including both direct and indirect emissions.

Prioritizing energy efficiency and environmental compliance not only aligns with global sustainability goals but also enhances operational efficiency and customer satisfaction.

Customization capabilities are a significant advantage when selecting a ERW tube mill manufacturer. Chinese pipe mills offer:

Custom pipe fabrication offers the following advantages:

Choosing a manufacturer with strong customization capabilities ensures that your specific project requirements are met, leading to higher customer satisfaction.

A proven track record in global projects is a testament to a manufacturer’s reliability and quality. Market standing is a critical indicator of a supplier’s ability to meet promises on quality and service. Assessing a supplier’s track record through proven past performances and references from previous clients provides valuable insights into their reliability.

Choosing an experienced manufacturer with a proven track record instills confidence in their ability to deliver high-quality products and exceptional service, ensuring long-term performance and a reliable partner with very reputable manufacturers.

In summary, selecting a reliable ERW tube mill manufacturer from China involves careful consideration of several critical factors. By assessing the manufacturer’s reputation, evaluating their production capacity and technical expertise, ensuring quality assurance and certifications, and prioritizing advanced technology and innovation, you can make an informed decision that meets your business needs.

Additionally, conducting a thorough cost analysis, ensuring robust after-sales support and maintenance services, and evaluating spare parts availability and energy efficiency are essential for long-term success. Customization capabilities and a proven track record in global projects further enhance the reliability and quality of the manufacturer. By following these guidelines, you can choose a manufacturer that offers exceptional value and supports your business goals.

Assess the reputation of a ERW tube mill manufacturer by evaluating customer reviews, seeking industry references, analyzing their market presence, and considering their longevity in the industry. This comprehensive approach will provide a clear picture of their reliability and trustworthiness.

You should seek ERW tube mill manufacturers with certifications such as EN 10204 3.1, ISO 9001, and compliance with international standards like ASME B36.10M and ASTM to ensure quality and reliability.

After-sales support is essential when selecting a ERW tube mill manufacturer, as it facilitates ongoing maintenance, spare parts management, and the long-term performance of the equipment. Ensuring robust support can significantly enhance the reliability and efficiency of your operations.

Advanced technology plays a crucial role in tube manufacturing by improving efficiency and quality through precise control of welding parameters and the implementation of automated systems. This leads to a more consistent and reliable production process.

Energy efficiency is crucial in tube manufacturing as it decreases long-term operating costs, minimizes environmental impact, and supports global sustainability efforts. Prioritizing energy efficiency not only benefits businesses economically but also contributes to a healthier planet.