The global demand for steel pipes continues to surge across construction, automotive, oil and gas, and various other industries. At the heart of this manufacturing boom lies the ERW tube mill – a sophisticated production system that transforms flat steel strips into high quality pipes through electric resistance welding technology. With the welded steel pipe market projected to exceed $250 billion by 2032, understanding ERW tube mills has become crucial for manufacturers, engineers, and investors alike.

This comprehensive guide explores everything from the fundamental principles of electric resistance welding to the latest technological advances reshaping the steel industry. Whether you’re evaluating equipment options, planning a new facility, or seeking to optimize existing operations, this article provides the technical insights and practical knowledge needed to make informed decisions about ERW tube mill investments.

An ERW tube mill represents a highly automated production line designed specifically for manufacturing welded tubes from flat steel strips. The term “ERW” stands for Electric Resistance Welding, which describes the core process where high-frequency electric current heats the edges of formed steel strip to create a permanent weld seam without requiring any filler material.

ERW tube mills transform coiled steel strips into round, square, or rectangular pipes through a continuous, highly efficient manufacturing process. The system begins with uncoiling flat steel material and progressively shapes it into a cylindrical form before applying electric resistance welding to join the edges. This method produces welded tubes that find applications across numerous industries, from water supply systems to structural applications.

The electric resistance welding process itself relies on the principle that electrical current passing through metal generates heat due to resistance. When high-frequency current (typically 100-800 kHz) flows through the steel strip edges, the resulting heat reaches temperatures sufficient for fusion. As the heated edges come together under pressure from forming rolls, they create a solid weld without any additional materials.

ERW tube mills offer several compelling advantages compared to seamless pipe production or other welding methods. The production speed of modern ERW mills typically reaches 120-150 meters per minute, with some advanced systems exceeding 200 m/min for lighter wall thickness applications. This remarkable efficiency translates to cost effective solutions for high-volume production requirements.

The process also delivers precise dimensional tolerance capabilities, often maintaining tolerances within ±0.1mm for diameter and wall thickness measurements. This precision makes ERW tubes particularly suitable for applications requiring consistent specifications, such as structural engineers designing building frameworks or manufacturing jobs requiring exact fit components.

Additionally, ERW mills demonstrate superior raw materials utilization compared to seamless production methods. The continuous process minimizes waste while maintaining consistent quality throughout extended production runs. The highly automated production line reduces labor requirements while ensuring reproducible results across different material types and size ranges.

The ERW tube mill manufacturing process involves a carefully orchestrated sequence of operations that transform flat steel strips into finished welded tubes. Understanding each stage helps manufacturers optimize production efficiency and maintain consistent quality standards.

The process begins with steel strip preparation, where large coils weighing several tons are positioned on uncoiling equipment. The uncoiler maintains precise tension control to ensure smooth feeding into the production line. As the steel strip enters the mill, it passes through leveling stations that eliminate any residual curvature or surface irregularities that could affect final tube quality.

To maintain continuous production, most ERW tube mill lines incorporate accumulation systems. These horizontal or vertical accumulators temporarily store excess strip material, allowing operators to join new coils without interrupting the welding process. The joining process typically involves shearing the coil ends square and butt welding them together, creating seamless handoffs between raw materials.

Edge preparation plays a critical role in weld quality. Some mills include edge trimming stations that remove any oxidation or surface contamination from the steel strip edges. This preparation ensures optimal conditions for the subsequent welding operation and helps prevent defects in the finished weld seam.

The heart of the ERW tube mill lies in its forming section, where flat steel strip gradually transforms into a cylindrical shape. This transformation occurs through a series of forming rolls arranged in multiple stands. Each forming stand bends the strip incrementally, avoiding excessive stress that could cause material damage or dimensional distortion.

The forming rolls are precision-engineered components designed for specific tube sizes and wall thickness ranges. Quick-change tooling systems allow mills to switch between different tube specifications with minimal downtime. The progressive forming approach ensures that the steel strip maintains its structural integrity while achieving the desired cylindrical shape.

As the formed strip approaches the welding station, the edges come together but remain unwelded. The precision of this edge alignment directly impacts final weld quality, making accurate forming roll setup crucial for producing high quality tubes.

The welding section represents the technological core of the ERW tube mill line. High-frequency welding units generate electrical current at frequencies between 100-800 kHz, which is applied to the steel strip edges through copper contact shoes or induction coils. This targeted heating approach concentrates energy precisely where welding occurs, maximizing efficiency while minimizing heat-affected zones.

The welding process requires careful control of multiple parameters including welding temperature, production speed, edge alignment, and pressure application. Modern ERW mills incorporate sophisticated control systems that monitor and adjust these variables in real-time, ensuring consistent weld quality across different material types and operating conditions.

Immediately after heating, squeeze rolls apply pressure to forge the heated edges together, creating the final weld. The pressure must be sufficient to achieve complete fusion while avoiding excessive material displacement that could affect tube dimensions or create surface defects.

Following the welding operation, the newly formed tube passes through sizing stations that establish final dimensions. These sizing rolls ensure consistent outer diameter and roundness while maintaining the integrity of the fresh weld seam. The sizing process also helps relieve internal stresses that may have developed during forming and welding.

Most ERW tube mill lines include weld bead removal systems that scarfe away excess material squeezed out during the welding process. This step creates smooth internal and external surfaces, which is particularly important for applications involving fluid transport or where surface finish affects functionality.

Quality control measures throughout the production line include continuous monitoring of dimensions, weld integrity testing using ultrasonic or eddy current methods, and periodic destructive testing to verify mechanical properties. These systems help ensure that finished products meet all relevant specifications and industry standards.

ERW tube mills are available in various configurations designed to meet specific production requirements, size ranges, and quality standards. Understanding the different types helps manufacturers select the most appropriate system for their particular applications and market focus.

Standard ERW tube mills represent the most common configuration, designed for producing round tubes across moderate size ranges with conventional wall thickness specifications. These mills typically handle outer diameters from 25mm to 200mm with wall thickness ranges from 1.5mm to 6mm, making them suitable for a wide variety of applications in construction, furniture manufacturing, and general industrial uses.

The production line configuration usually includes 8-12 forming stands, allowing gradual shaping that minimizes stress on the material while maintaining dimensional accuracy. Standard mills often incorporate modular designs that facilitate maintenance and allow some flexibility in tooling arrangements for different tube specifications.

These systems provide an excellent balance between capital investment and production capability, making them attractive options for manufacturers entering the welded tube market or those serving diverse customer requirements across multiple industries.

High-frequency precision ERW mills incorporate advanced welding technology and enhanced forming capabilities to produce tubes meeting stringent dimensional and quality requirements. These systems typically operate at higher frequencies (400-800 kHz) and include more sophisticated control systems for monitoring and adjusting process parameters.

Precision mills excel at producing tubes for demanding applications such as automotive components, hydraulic systems, and structural applications where dimensional consistency and mechanical properties are critical. The enhanced welding systems in these mills often achieve superior weld penetration and heat-affected zone control compared to standard configurations.

Investment costs for precision ERW mills are typically 20-30% higher than standard systems, but the premium is often justified by the ability to serve higher-value market segments and maintain tighter quality specifications that command premium pricing.

ERW tube mills are commonly classified by their size range capabilities, with each category optimized for specific diameter ranges and production requirements.

Small Diameter Mills (8mm to 100mm)

Small diameter ERW mills focus on producing precision tubes for applications such as automotive exhaust systems, hydraulic lines, and specialized industrial components. These mills often operate at higher production speeds due to the reduced material volume per linear meter, with some systems achieving speeds exceeding 300 meters per minute.

The compact size of the finished product allows for efficient material handling and packaging, making these mills particularly suitable for high-volume production scenarios. Raw materials for small diameter mills typically consist of thinner steel strips, requiring precise tension control and forming to prevent buckling or dimensional distortion.

Medium Range Mills (100mm to 500mm)

Medium range ERW mills represent the largest segment of the market, serving applications in construction, water supply, and general industrial uses. These systems offer versatility in producing both round and shaped tubes, with many mills capable of manufacturing square and rectangular profiles in addition to circular cross-sections.

The forming sections in medium range mills typically include 10-15 stands to accommodate the larger diameter and wall thickness variations. Production speeds generally range from 60-120 meters per minute, depending on material type and wall thickness requirements.

Large Diameter Mills (500mm to 864mm)

Large diameter ERW mills target applications in infrastructure, large-scale construction, and specialized industrial projects. These systems require substantial capital investment but serve market segments with limited competition and higher profit margins.

The engineering challenges in large diameter mills include managing the increased forming forces, ensuring weld quality across thicker wall sections, and maintaining dimensional accuracy despite the scale of the operation. These mills often incorporate special forming techniques and enhanced welding systems to address these technical requirements.

Understanding the critical components of an ERW tube mill helps manufacturers evaluate equipment options, plan maintenance requirements, and optimize production performance. Each major system contributes to overall mill capability and product quality.

The uncoiling system serves as the foundation of the entire production line, requiring robust construction to handle coils weighing up to 25 tons while maintaining precise strip feeding. Modern uncoilers incorporate hydraulic expansion systems that securely grip the coil interior, preventing slippage during high-speed operation.

Tension control systems monitor and adjust strip tension throughout the feeding process, preventing excessive stress that could cause material yielding or dimensional variations. Advanced systems include dancer roll assemblies and load cells that provide continuous feedback to maintain optimal tension regardless of coil diameter changes as material unwinds.

Many ERW tube mill lines include strip conditioning equipment such as edge trimmers and surface cleaning systems. These components ensure that raw materials enter the forming section in optimal condition for subsequent processing operations.

The forming section represents the mechanical heart of the ERW tube mill, where precision engineering determines the quality and accuracy of the finished product. Forming stands are typically arranged in a progressive sequence, with each stand contributing a specific amount of forming to achieve the final shape.

Stand construction usually features heavy-duty frames designed to withstand the substantial forces generated during forming operations. The stands must maintain precise alignment under load while providing accessibility for tooling changes and maintenance operations.

Modern forming stands often incorporate servo-driven positioning systems that allow rapid setup adjustments and automatic compensation for tooling wear. These systems significantly reduce changeover times while improving consistency across different production runs.

The welding system represents the most technologically sophisticated component of the ERW tube mill line. High-frequency generators must deliver precise power control across a wide range of operating conditions while maintaining stability during production speed variations.

Welding heads incorporate water-cooled components to handle the thermal loads generated during high-speed operation. The copper contact shoes or induction coils require regular maintenance and replacement, making accessibility and quick-change designs important considerations in equipment selection.

Modern welding systems include real-time monitoring of welding parameters, with automatic adjustments to maintain optimal conditions as production variables change. These systems can detect and compensate for material variations, speed changes, and other factors that might affect weld quality.

Sizing stations ensure that welded tubes meet dimensional specifications while relieving internal stresses developed during forming and welding. The sizing rolls must be precisely manufactured and maintained to achieve the tight tolerances required in many applications.

Calibration systems often include multiple sizing passes, each designed to gradually achieve final dimensions without overstressing the material or damaging the fresh weld seam. The sizing process also helps improve roundness and straightness, particularly important for structural applications and precise fit requirements.

Advanced sizing systems incorporate real-time dimensional monitoring with feedback control to maintain specifications despite tool wear and thermal effects. These systems can detect dimensional drift and make automatic adjustments to maintain quality standards.

The cutting section must cleanly separate the continuous tube into specified lengths while maintaining cut quality and dimensional accuracy. Flying saws represent the most common cutting method, allowing operation without interrupting the continuous production flow.

Cut-to-length accuracy is crucial for many applications, particularly in construction and manufacturing where precise lengths reduce waste and improve assembly efficiency. Modern cutting systems achieve accuracies within ±3mm across standard length ranges.

Material handling systems downstream of the cutting operation include automatic stacking, bundling, and identification systems. These automated systems reduce labor requirements while ensuring proper organization and traceability of finished products.

ERW tubes serve diverse market sectors, each with specific requirements for dimensions, mechanical properties, and quality standards. Understanding these applications helps manufacturers position their production capabilities and identify growth opportunities.

The construction sector represents the largest market for ERW tubes, consuming millions of tons annually for structural applications, building frameworks, and infrastructure projects. Hollow structural sections (HSS) produced on ERW tube mills provide excellent strength-to-weight ratios for building construction, making them preferred choices for structural engineers designing modern facilities.

ERW tubes in construction applications typically require compliance with standards such as ASTM A500 or EN 10219, which specify mechanical properties, dimensional tolerances, and testing requirements. The precise dimensional tolerance capabilities of modern ERW mills make them particularly suitable for prefabricated construction systems where components must fit together accurately.

Square and rectangular ERW tubes find extensive use in building frameworks, where their clean lines and consistent dimensions facilitate efficient construction processes. The ability to produce these shapes efficiently gives ERW mills advantages over seamless pipe production for many construction applications.

The automotive sector demands ERW tubes meeting stringent specifications for weight reduction, strength requirements, and dimensional consistency. Applications include chassis components, exhaust systems, and safety structures such as roll cages and crash energy management systems.

Automotive ERW tubes often require advanced high-strength steels (AHSS) that present forming and welding challenges requiring specialized mill capabilities. The ability to process these materials effectively opens access to premium market segments with higher profit margins.

Quality requirements in automotive applications typically exceed those in general construction, with zero-defect expectations and comprehensive traceability requirements. ERW mills serving this market must incorporate advanced quality control systems and statistical process control methods.

While seamless pipes dominate high-pressure applications, ERW tubes serve important roles in oil and gas infrastructure for lower-pressure applications and gathering systems. API 5L specifications govern ERW tubes used in pipeline construction, requiring specific mechanical properties and testing protocols.

The oil and gas industry values the cost effectiveness of ERW production for applications where the welded seam does not compromise performance. Modern ERW mills can produce API-grade line pipe meeting stringent requirements for pipeline construction projects worldwide.

Specialized coatings and corrosion protection systems often supplement ERW tubes in oil and gas applications, requiring coordination between tube manufacturers and coating facilities to deliver complete pipeline solutions.

Municipal water supply systems rely heavily on ERW tubes for distribution networks, with specifications typically governed by AWWA or similar standards. The smooth internal surfaces achievable with ERW production contribute to efficient water flow and reduced maintenance requirements.

Water supply applications often require larger diameter tubes than traditional ERW mills could produce, but advances in mill technology have expanded the size range capabilities to serve this growing market segment. The cost effectiveness of ERW production makes it attractive for large infrastructure projects where budget constraints are significant factors.

Corrosion resistance requirements in water supply applications often drive material selection toward galvanized or coated ERW tubes, requiring coordination between tube manufacturers and finishing facilities.

Investing in an ERW tube mill represents a significant financial commitment requiring careful analysis of market conditions, technical requirements, and financial projections. Understanding the key business factors helps potential investors make informed decisions about equipment acquisition and facility development.

ERW tube mill investments typically range from $2 million for basic small-diameter systems to over $20 million for large, high-capacity lines with advanced automation. The investment scale depends heavily on the size range, production capacity, automation level, and quality requirements for the intended market applications.

Equipment costs represent approximately 60-70% of total project investment, with facility construction, utilities, and working capital comprising the remainder. The largest private investment decisions often involve comprehensive feasibility studies that evaluate market potential, competition analysis, and long-term profitability projections.

Financing options for ERW tube mill projects include traditional bank loans, equipment leasing arrangements, and specialized industrial financing programs. Many equipment suppliers offer financing assistance or leasing programs that can reduce initial capital requirements while preserving working capital for operations.

Raw materials typically represent 70-80% of operating costs in ERW tube production, making steel strip procurement and inventory management critical success factors. Effective supply chain management can significantly impact profitability, particularly in volatile steel markets.

Labor costs in modern ERW mills are relatively modest due to high automation levels, but skilled maintenance personnel and quality control specialists are essential for optimal performance. Training programs and technical support from equipment suppliers help ensure efficient operations and minimize downtime.

Utility costs, particularly electricity for high-frequency welding operations, represent another significant operational expense. Energy-efficient welding systems and optimized production scheduling can help minimize these costs while maintaining production targets.

Successful ERW tube mill investments require thorough market analysis covering local demand patterns, competition assessment, and growth projections. The steel industry experiences cyclical demand patterns that can significantly impact profitability, making timing an important consideration in investment decisions.

Geographic proximity to major consumption centers often provides competitive advantages through reduced transportation costs and improved customer service capabilities. Understanding regional construction activity, industrial development, and infrastructure investment plans helps predict future demand levels.

Competition analysis should evaluate both local ERW producers and imports from other regions. Understanding competitor capabilities, pricing strategies, and market positioning helps identify opportunities for differentiation and competitive advantage.

ERW tube mill investments typically target payback periods of 3-5 years, depending on market conditions and operational efficiency levels. ROI calculations must consider production capacity utilization rates, which significantly impact unit costs and profitability.

Premium market segments often justify higher equipment investments through improved margins and more stable demand patterns. Serving specialized applications or maintaining superior quality standards can support pricing premiums that enhance overall returns.

Risk factors affecting ROI include steel price volatility, demand fluctuations, competition from imports, and regulatory changes affecting target markets. Sensitivity analysis helps evaluate how these factors might impact financial performance under different scenarios.

Choosing the right ERW tube mill supplier represents one of the most critical decisions affecting long-term project success. The complexity of these systems requires careful evaluation of technical capabilities, experience, and support services.

Evaluating supplier technical capabilities begins with reviewing their design approach and understanding how their systems address specific production requirements. Suppliers should demonstrate experience with similar applications and provide detailed specifications covering all critical performance parameters.

References from existing customers provide valuable insights into actual performance versus promised capabilities. Site visits to operating mills allow direct observation of equipment performance and discussions with operators about reliability, maintenance requirements, and technical support quality.

The supplier’s engineering team depth and experience significantly influence project success. Understanding their capability to customize standard designs for specific requirements helps ensure that the delivered system meets all production objectives.

Supplier manufacturing experience directly correlates with equipment reliability and performance consistency. Companies with extensive ERW mill manufacturing history typically have refined their designs through multiple projects and resolved common technical challenges.

Successful project references should include systems similar in size, capacity, and application to the planned investment. References should cover not only technical performance but also project execution, commissioning support, and ongoing service quality.

International suppliers may offer cost advantages but require careful evaluation of their ability to provide ongoing support and spare parts availability. Local representation or service partnerships can help address these concerns while maintaining cost competitiveness.

After sales service capabilities are crucial for maintaining high productivity and minimizing downtime throughout the equipment lifecycle. Suppliers should provide comprehensive service programs including preventive maintenance, spare parts supply, and technical support.

Training programs for operators and maintenance personnel help ensure optimal equipment performance and extend component life. Suppliers should offer both initial training during commissioning and ongoing education programs to maintain skill levels as personnel change.

Remote monitoring and diagnostic capabilities allow suppliers to provide proactive support and identify potential issues before they cause production interruptions. These services are increasingly important as mills become more complex and automation levels increase.

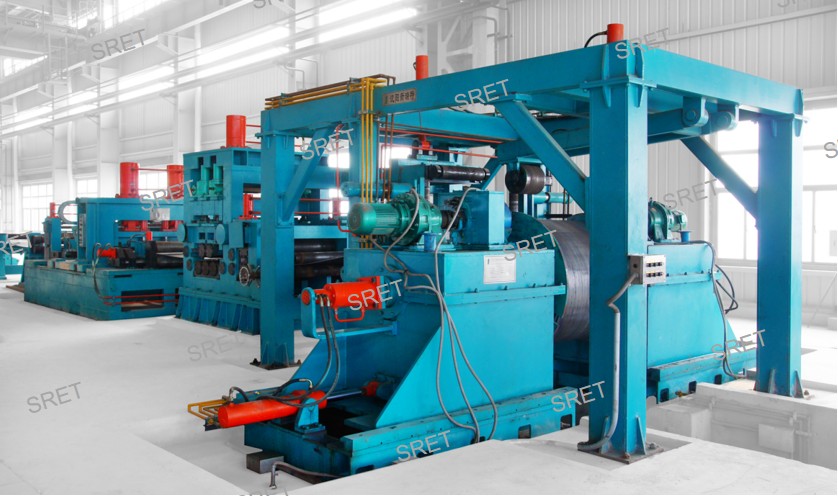

In the dynamic landscape of industrial machinery, the demand for high-quality ERW (Electric Resistance Welded) tube mill equipment continues to surge, driven by global infrastructure development, automotive production, and energy sector expansion. As industries seek reliable, efficient, and innovative solutions, choosing the right ERW tube mill supplier becomes paramount. Among the frontrunners in China’s manufacturing sector, Shenyang SRET Tech Co., Ltd. (SRET) stands out as a trusted pioneer and leader, with a legacy of excellence spanning over three decades.

Founded in 1989 in Shenyang, Liaoning Province, by five university senior professors, SRET began with a visionary mission: to become an industrial pioneer in China’s tube mill machine manufacturing. For 30 years, this vision has been transformed into reality through unwavering commitment to continuous innovation and quality improvement. Today, SRET has solidified its position as an industry leader, renowned for designing, engineering, manufacturing, and supplying a full range of ERW tube mill machinery tailored to diverse application needs.

What sets SRET apart is its decades of specialized experience and expertise. The company’s success is rooted in a dual strength: a highly qualified engineering team that pushes the boundaries of technological advancement, and an experienced production team that ensures precision and reliability in every piece of equipment. This synergy guarantees that customers receive exactly the machinery they desire, meeting the most rigorous engineering and design expectations.

SRET’s ERW tube mill machinery is engineered to deliver top-quality performance and produce high-grade tubes, catering to industries such as construction, oil and gas, automotive, and manufacturing. The company’s commitment to quality is evident in its stringent production standards, use of advanced materials, and adherence to international benchmarks. Whether for small-scale operations or large industrial projects, SRET’s equipment is designed to optimize efficiency, reduce downtime, and enhance productivity—key factors that drive customer success.

Beyond manufacturing excellence, SRET prides itself on its customer-centric approach. The company’s comprehensive service model spans the entire lifecycle of a project:

For businesses seeking a reliable ERW tube mill supplier in China, SRET offers unparalleled advantages:

In an era where industrial excellence is defined by innovation, reliability, and customer focus, SRET Co., Ltd. emerges as the best ERW tube mill supplier in China. With its rich legacy, cutting-edge technology, and unwavering commitment to quality, SRET continues to set the standard for the industry, empowering businesses worldwide to achieve their production goals. For those seeking a partner they can trust, SRET is more than a supplier—it is a catalyst for success in the global ERW tube manufacturing landscape.

To learn more about SRET’s products and services, visit their official website: https://www.sret-tech.com/erw-tube-mill-line-machine/.

Quality standards and specifications govern ERW tube production across all major market sectors, ensuring product safety, reliability, and performance consistency. Understanding these requirements helps manufacturers design production systems and quality control programs that meet customer expectations.

ASTM International provides comprehensive standards covering ERW tube production for various applications. ASTM A53 governs general-purpose ERW pipe for pressure applications, while ASTM A500 specifies requirements for cold-formed welded structural tubing used in construction applications.

These standards define mechanical property requirements, dimensional tolerances, testing procedures, and quality control protocols that manufacturers must follow to supply certified products. Compliance requires comprehensive testing programs and documentation systems that provide traceability from raw materials through final inspection.

ASTM standards also specify marking and identification requirements that help ensure proper material selection and application. Manufacturing facilities must implement systems that maintain material traceability and prevent mixing of different grades or specifications.

ISO 9001 quality management systems provide the framework for comprehensive quality control in ERW tube manufacturing. These systems ensure consistent processes, continuous improvement, and customer satisfaction through systematic approach to quality management.

ISO 14001 environmental management standards are increasingly important as customers and regulators focus on environmental responsibility. ERW mills must demonstrate compliance with environmental regulations and implement systems that minimize environmental impact.

Quality management systems must address all aspects of production from incoming material inspection through final product testing and delivery. Documentation requirements ensure that quality control procedures are followed consistently and that any issues can be traced to their sources.

Modern ERW tube mills routinely achieve dimensional tolerances within ±0.1mm for outer diameter and wall thickness measurements. These precise dimensional tolerance capabilities are essential for applications requiring accurate fit-up or where dimensional consistency affects performance.

Surface finish requirements vary significantly across applications, from basic mill finish for structural applications to precision finished surfaces for hydraulic components. Mill capability to achieve various surface finishes affects market positioning and pricing opportunities.

Roundness and straightness specifications are particularly important for structural applications and precision manufacturing. ERW mills must maintain these geometric tolerances across the full length of produced tubes while accommodating variations in raw material properties.

Mechanical property requirements for ERW tubes include tensile strength, yield strength, elongation, and impact toughness specifications that vary according to application requirements. The welding process and heat treatment can significantly affect these properties, requiring careful process control.

Weld seam integrity represents a critical quality parameter that requires both destructive and non-destructive testing protocols. Testing programs must verify that weld properties meet or exceed base material specifications across all production conditions.

Quality control testing frequency depends on application requirements and customer specifications. High-volume production often utilizes statistical sampling plans that provide confidence in product quality while maintaining production efficiency.

The ERW tube mill industry continues evolving through technological advances, automation improvements, and sustainability initiatives that enhance production efficiency and product quality while reducing environmental impact.

Modern ERW tube mills incorporate comprehensive automation systems that monitor and control all aspects of production from material handling through final inspection. These systems reduce labor requirements while improving consistency and quality control throughout the production process.

Industry 4.0 technologies including artificial intelligence, machine learning, and predictive analytics are transforming ERW mill operations. These systems can optimize production parameters in real-time, predict maintenance requirements, and identify quality issues before they affect product quality.

Data collection and analysis capabilities enable manufacturers to optimize production efficiency, reduce waste, and improve overall equipment effectiveness. The ability to analyze vast amounts of production data provides insights that drive continuous improvement and competitive advantage.

Environmental consciousness drives innovation in ERW mill design and operation, with focus on energy efficiency, emissions reduction, and waste minimization. High-frequency welding systems have become significantly more energy efficient, reducing both operating costs and environmental impact.

Recycling programs for steel waste and scrap materials help minimize environmental impact while recovering valuable materials. Modern mills design their operations to maximize material utilization and minimize waste generation throughout the production process.

Water usage and treatment systems ensure that mill operations meet environmental regulations while minimizing resource consumption. Closed-loop cooling systems and water recycling technologies reduce overall environmental footprint of ERW tube production.

ERW mills are increasingly capable of processing advanced high-strength steels and specialized alloys that were previously limited to seamless production methods. These capabilities open new market opportunities in automotive, aerospace, and specialized industrial applications.

Specialized welding techniques and enhanced process control enable processing of materials with specific metallurgical requirements. The ability to maintain precise heat control and welding parameters allows successful processing of materials that require careful thermal management.

Coating and surface treatment integration allows mills to deliver finished products that meet complete customer specifications. This integration reduces handling and transportation costs while ensuring quality throughout the entire production chain.

The global ERW tube market continues expanding as infrastructure development, construction activity, and industrial growth drive demand for cost effective solutions in steel tube production. Emerging markets particularly show strong growth potential as economic development accelerates construction and industrial activity.

Technology transfer and knowledge sharing between developed and emerging markets help establish new production capabilities while maintaining quality standards. This trend supports global market growth while providing opportunities for equipment suppliers and technology providers.

The future outlook for ERW tube mills includes continued automation advancement, improved energy efficiency, and enhanced capabilities for processing advanced materials. These developments will maintain the competitiveness of ERW production methods while expanding into new application areas and market segments.

Modern ERW tube mills represent sophisticated manufacturing systems that combine proven welding technology with advanced automation and quality control capabilities. The electric resistance welding process offers unique advantages in production speed, dimensional accuracy, and cost effectiveness that make it suitable for a wide range of applications across multiple industries.

Success in ERW tube manufacturing requires careful attention to market analysis, equipment selection, quality control, and operational efficiency. The right tube mill configuration, supported by appropriate supplier relationships and comprehensive quality systems, can provide the foundation for profitable operations in this competitive but growing market.

As the steel industry continues evolving toward greater automation, environmental responsibility, and advanced materials processing, ERW tube mills will remain essential manufacturing tools for producing the welded tubes that support modern construction, transportation, and industrial infrastructure worldwide.