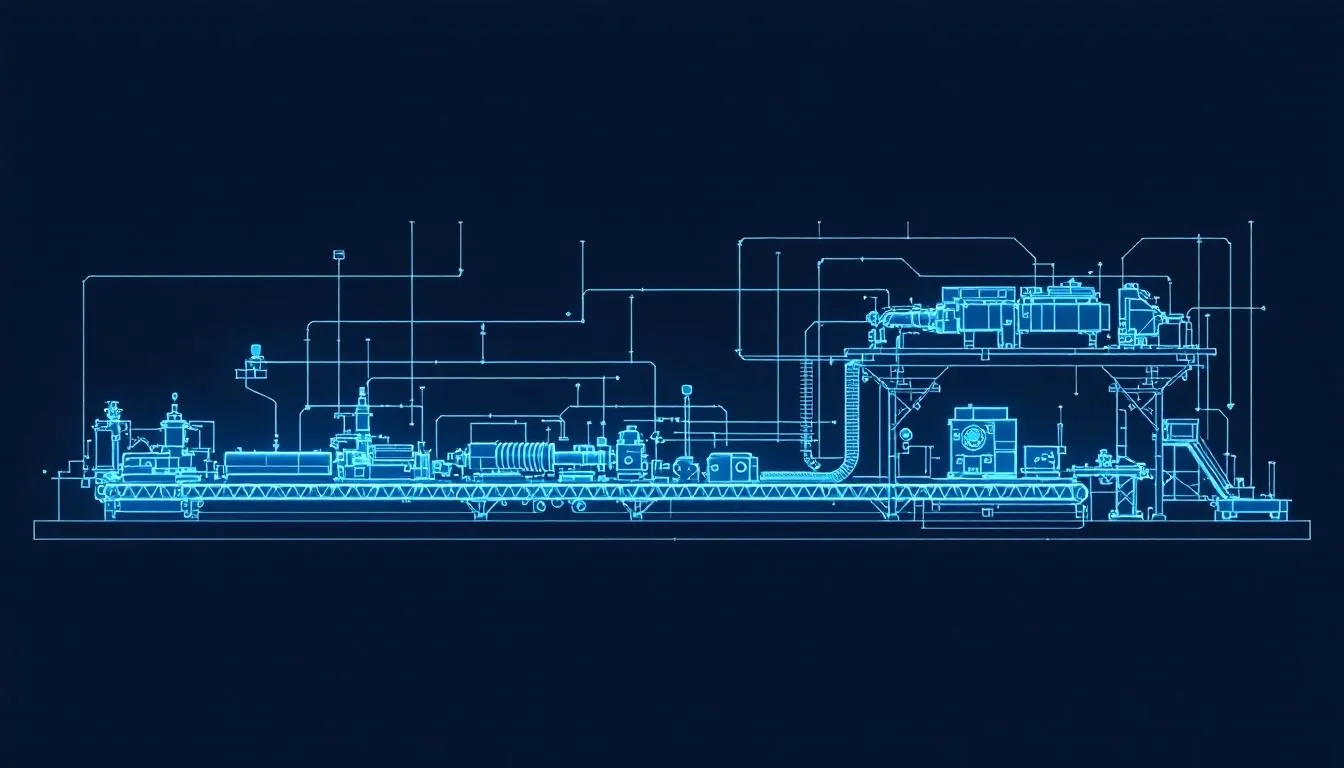

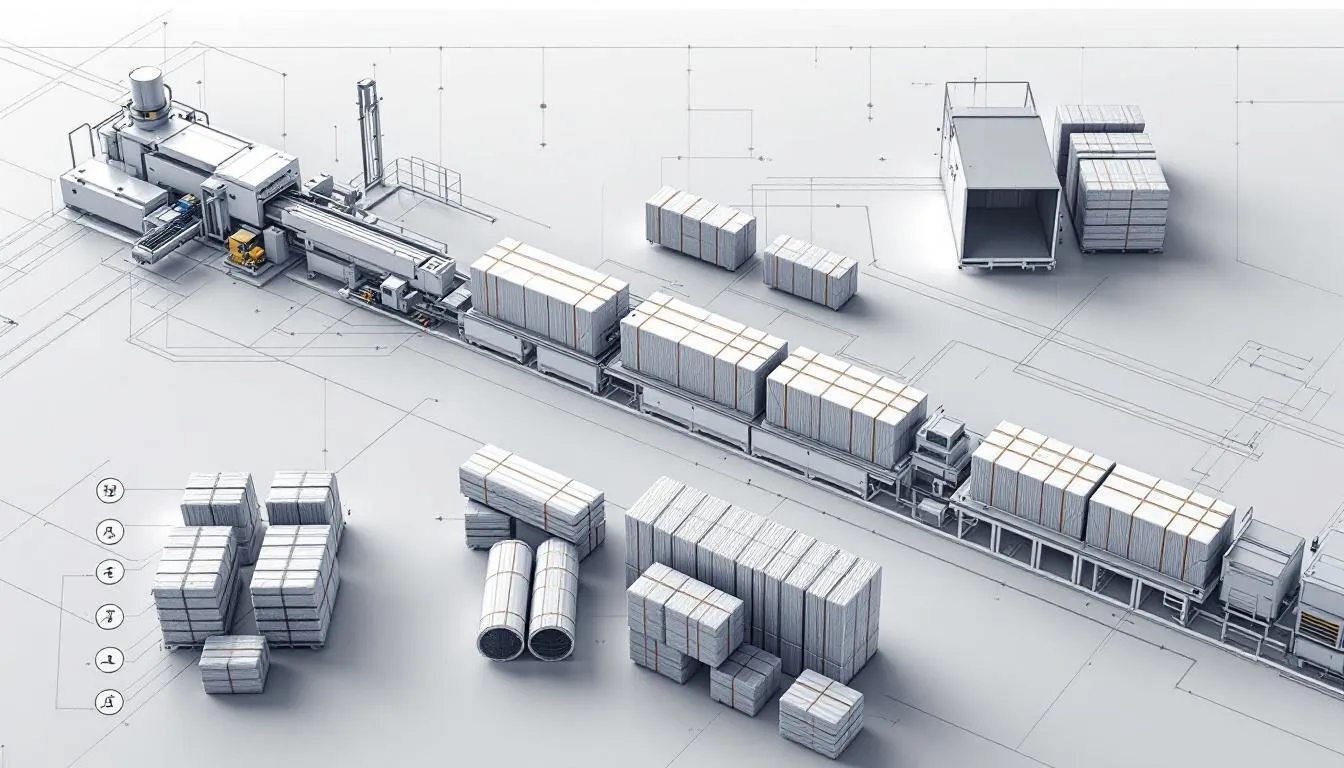

Looking to understand how ERW tube mill lines manufacture high-quality steel pipes efficiently? An ERW tube mill line uses electric resistance welding for strong welds, essential in industries like construction and automotive. This article dives into the core components, the production process, and the advantages of ERW tube mill lines, providing clear insights into their importance in pipe manufacturing.

ERW tube mill lines are the backbone of modern pipe manufacturing, providing a reliable and efficient method for producing high-quality steel pipes. At the heart of this technology is the process of electric resistance welding (ERW), which involves forming a continuous weld from the edges of rolled steel sheets. This precision welding ensures that the pipes produced are not only strong but also meet stringent industry standards in the pipe mill.

ERW tube mill lines play a crucial role in producing steel pipes for various applications, such as construction, automotive, and furniture manufacturing. Their reliability and strength make ERW tubes indispensable in these industries, where quality is paramount.

For those in the manufacturing sector, grasping the intricacies of ERW tube mill lines is essential. The types of ERW pipes and the key components of these production lines are vital in ensuring efficiency and quality. Here’s an overview of what an ERW tube mill line is and its key components.

An ERW tube mill line is a specialized facility that manufactures pipes using the process of electric resistance welding. This process involves joining the edges of steel strips by applying pressure and passing an electric current through them, creating a strong and continuous weld seam. The result is a high-quality pipe that can be used in various applications, including those produced by an erw pipe mill.

There are two main types of ERW pipes: ERW AC welding steel pipes and ERW DC welded steel pipes. ERW seam-welded tubes are classified based on frequency. They include low-frequency, medium-frequency, and supercurrent welding pipes. Manufacturers can also customize the configurations to produce round, square, and rectangular pipes, catering to specific customer needs.

At the core of ERW tube mill lines lies the steel coil, the primary raw material used in the production process. These coils are meticulously shaped into tubes using forming rolls, which ensure the precise dimensions required for high-quality pipes. The integrity and strength of the pipes are maintained through the weld seams, which are critical in ensuring that the final product meets industry standards.

Automation equipment plays a pivotal role in enhancing the efficiency of ERW tube mill lines. Automation streamlines the production process and minimizes the need for manual intervention, leading to smoother operations, higher output, and reduced operational costs.

ERW tubes are used across a wide range of industries due to their strength and reliability. In the construction industry, they are commonly used for scaffolding and structural frames, providing the necessary support for various building projects. The automotive industry also relies on ERW tubes for components such as exhaust systems, where durability and precision are essential.

In recent years, ERW tube mills have been established in regions like South America to meet the growing demand for steel pipes in sectors such as construction and automotive. These mills have achieved production speeds of up to 120 meters per minute, showcasing the efficiency and effectiveness of ERW tube mill lines.

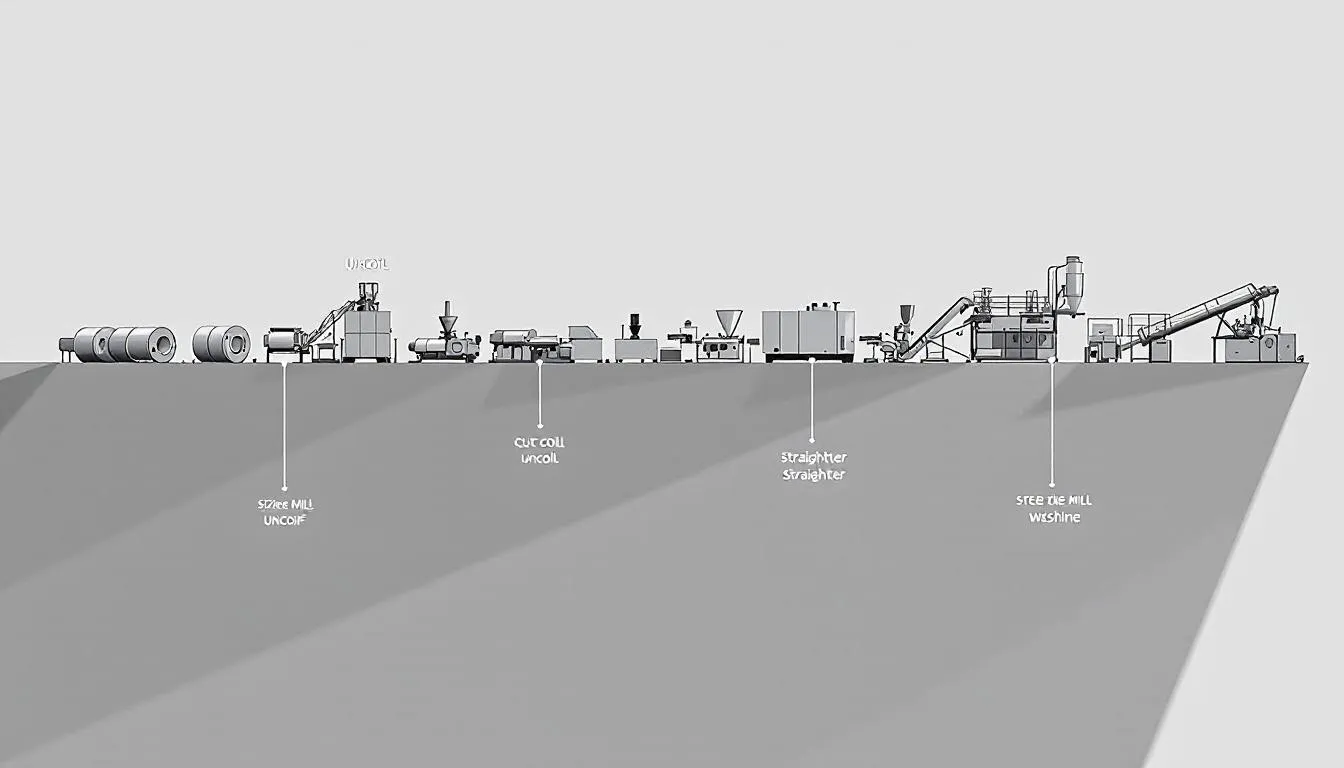

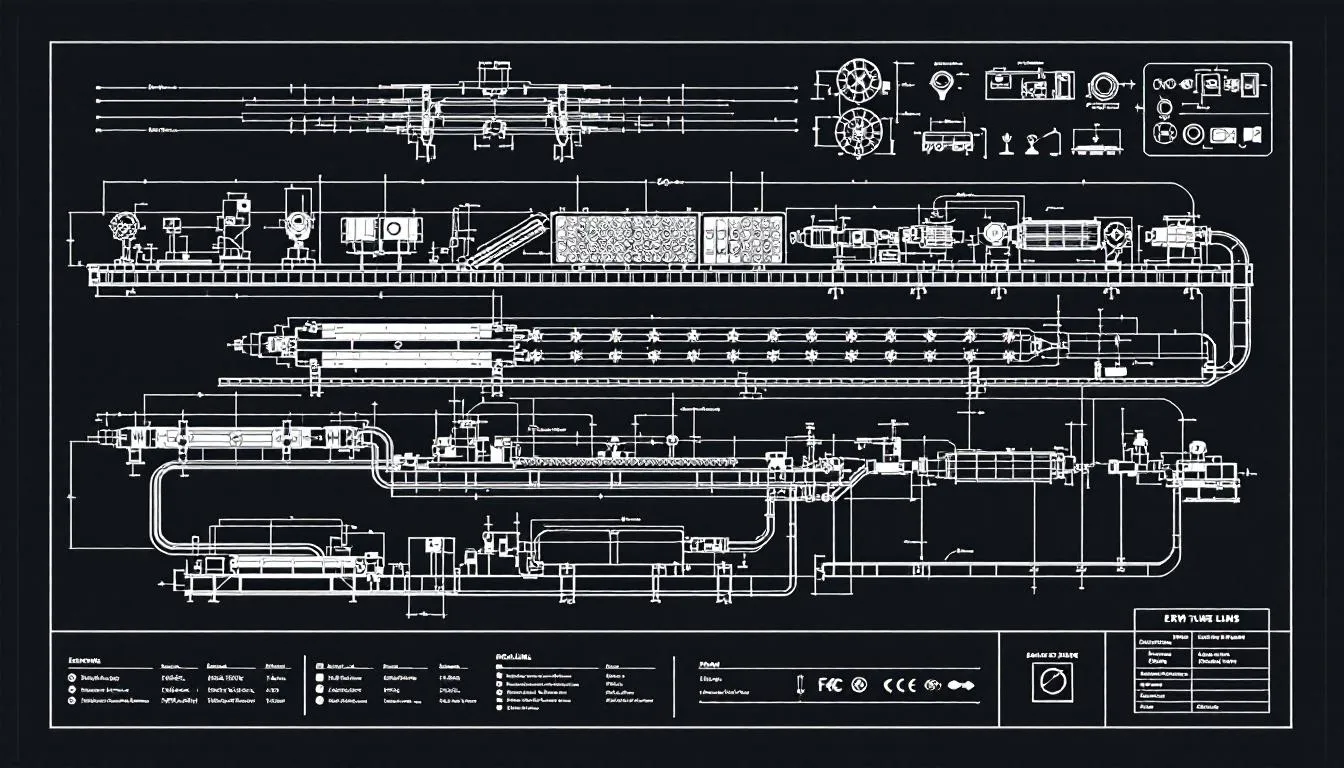

The journey of transforming a steel coil into a finished tube in an ERW tube mill line involves several meticulously designed stages:

Each step is crucial in ensuring the production of high-quality pipes.

Understanding the process flow of ERW tube mill lines reveals valuable insights into their operation and the critical importance of each stage. Here are the specifics of steel coil preparation, forming section and welding, and cutting and finishing.

The preparation of steel coils is the first step in the ERW tube mill line process. Steel coils are initially uncoiled and flattened to eliminate any curvature, ensuring a smooth start to the forming process. This step is essential in preventing defects and ensuring the quality of the final product.

Before entering the tube mill, steel coils undergo thorough cleaning and inspection to remove contaminants that could affect welding and to ensure they meet quality standards, even in the presence of heat.

The forming process in an ERW tube mill line involves:

Precision alignment during welding prevents defects and ensures the proper structure of ERW tubes. Rigorous quality control measures monitor welding parameters to guarantee the final product meets high standards of quality and durability.

Once the welding process is complete, the continuous tube is cut to specified lengths using a flying cutoff machine. This high-speed operation ensures that the production process remains efficient and minimizes downtime. The tubes are then subjected to finishing processes, such as removing burrs and preparing the surface, to ensure that the final product meets the required quality standards.

The streamlined production process in ERW tube mills results in quick turnaround times and reduced lead times for projects. This efficiency is crucial in meeting the demands of various industries and ensuring timely delivery of high-quality pipes.

ERW tube mill lines offer numerous advantages that make them the preferred choice for producing high-quality steel pipes. These advantages include high production efficiency, precision and quality control, and cost-effectiveness. The automated and efficient production processes in ERW tube mills significantly reduce labor costs and enhance production rates, making them an essential component in modern manufacturing.

The implementation of advanced filtration technology and automation systems in ERW tube mills has led to reduced operational costs and improved productivity. These mills are known for their ability to produce durable and high-quality steel pipes, which are crucial for various applications in industries such as construction and automotive.

Let’s explore the specific advantages of ERW tube mill lines in more detail, focusing on high production efficiency, precision and quality control, and cost-effectiveness.

ERW tube mills are designed to operate at high production speed, with some mills capable of reaching up to 120 meters per minute. This high production efficiency is achieved through advanced automation systems that minimize operational downtime and maximize output. For example, in the automotive sector, ERW tube mills have enhanced the production of lightweight and high-strength pipes, contributing to more fuel-efficient vehicles.

Efficient ERW tube mill production techniques lower costs per unit by reducing waste and defects. Customers have reported significant time savings, with roller change time reduced to just 10 minutes. This efficiency is vital for meeting industry demands and ensuring timely delivery of high-quality products.

Precision is a key advantage in ERW tube production. Forming rolls ensure precise dimensioning, essential for applications with tight tolerances. High-frequency induction welding bonds the edges of the steel strip without filler material, creating a clean, strong weld.

Modern ERW tube mills incorporate automated systems that enhance production efficiency and quality control. These systems ensure strict adherence to dimensional accuracy, minimizing defects during production. Satisfaction regarding product quality has been expressed, particularly in the consistent precision of the weld seams across various applications.

Cost-effectiveness is another compelling advantage of ERW tube mill lines. These production lines are vital for producing high-quality steel pipes, significantly impacting industries like construction and automotive. Over 15 years of R&D and manufacturing experience contribute to their efficient production.

Efficient production processes and strict quality control in ERW tube mill lines lead to significant cost savings and reduced defect rates. Customers praise the consistent quality and reliability of ERW tube mills, crucial for maintaining competitive production schedules.

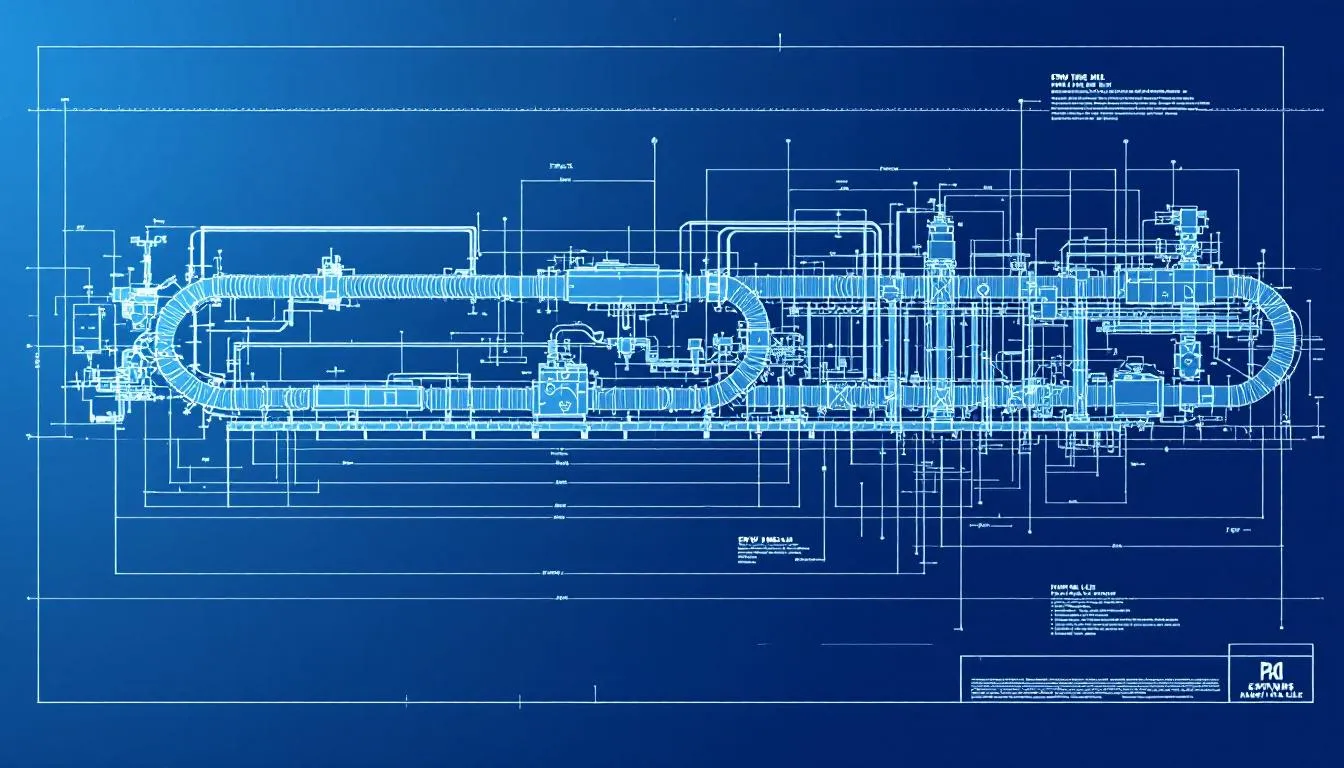

Technical specifications play a crucial role in determining the efficiency and quality of ERW tube mill lines. These specifications include material types, production capacities, and equipment data. Successful ERW tube mill installations have significantly improved production capacities, allowing companies to meet higher demand efficiently.

High-grade steel and alloys are commonly utilized in ERW tube mill lines to ensure product quality. The capability to produce pipes in a variety of dimensions, including various diameter ranges and wall thicknesses, makes ERW tube mill lines versatile for different applications.

Let’s delve into the material specifications, production capacities, and equipment data that define the technical aspects of ERW tube mill lines.

The choice of materials used in ERW tube production is critical to ensure the strength and durability of the final product. Common materials for ERW tube production include various grades of steel, such as carbon steel and alloy steel, which are suitable for a wide range of industrial applications. These materials are selected based on their ability to withstand high pressure and corrosive environments, making them ideal for sectors such as the chemical industry and construction.

The thickness and width of steel coils are crucial factors that directly affect the final dimensions of the ERW tubes produced. Manufacturers must adhere to specific customer requirements to ensure the tubes meet the necessary standards for their intended use.

The availability of raw materials for ERW tubes is generally better than for seamless tubes, contributing to their lower production costs and making them a cost-effective solution for various projects.

The production capacities of ERW tube mills are impressive, including:

This versatility enhances the capability of ERW tube mills to meet diverse industry needs.

ERW tube mills are designed to produce a wide range of pipe dimensions, making them suitable for various industries. This adaptability ensures that manufacturers can supply high-quality pipes that meet the specific needs of their clients, whether they require pipes for construction, automotive, or other applications, including erw pipe mills.

ERW tube mill equipment is sophisticated and designed for high-speed production demands. For instance, Hebei Tubo Machinery Co., LTD specializes in developing and manufacturing equipment for High Frequency Welded Pipe Production Line and Large-size Square Tube Cold Forming Line. The company covers all aspects of the production process with its range of equipment, including welded tube/pipe mills, cold roll forming machines, and slitting lines.

The total foundation length required for an ERW mill can range from 40 meters to 400 meters, depending on the machine specifications, while the total weight of ERW tube mill equipment can range from 30 tons to over 300 tons. These specifications highlight the considerable scale and capability of ERW tube mills, making them a powerful solution for high-volume pipe production.

ERW tube mill lines provide remarkable customization and flexibility, enabling manufacturers to tailor the production process to meet specific customer requirements. This adaptability is essential for producing various pipe shapes and sizes, catering to diverse market demands. Modifying production methods and specifications ensures ERW tube mills can meet the unique needs of each project.

Integrating advanced technology in ERW tube mills enhances their flexibility and precision. Modern roll forming technologies and automation systems enable manufacturers to achieve complex profiles and reduce setup times, resulting in more efficient and precise production processes.

Customer support and after-sales service are crucial components of the ERW tube mill experience. Manufacturers provide services such as:

Customization of ERW tube mill lines is essential for manufacturers to produce pipes that meet diverse market demands. Tailoring the production process to specific customer requirements allows manufacturers to create a wide variety of pipe shapes and sizes, catering to different industries such as construction, automotive, and furniture manufacturing. This flexibility ensures each project receives the perfect solution.

Manufacturers offer a range of customization options, including adjustments in pipe diameter, wall thickness, and production methods. These tailored solutions enable manufacturers to meet specific customer requirements, providing pipes that are perfectly suited to their intended applications.

The integration of advanced technology in ERW tube mills plays a pivotal role in enhancing precision and flexibility. Modern roll forming technologies enable the creation of complex profiles with reduced setup times, leading to more efficient and precise production. Automation systems further enhance efficiency by minimizing operational downtime and ensuring consistent quality.

By incorporating advanced technology, ERW tube mills can achieve higher production speeds and improved product quality, making them a valuable asset in the manufacturing sector. The ability to integrate modern technology ensures that ERW tube mills remain competitive and capable of meeting the evolving demands of various industries.

Customer support and after-sales service are essential for the longevity and efficient operation of ERW tube mill lines. Manufacturers offer services such as:

The availability of professional teams dedicated to researching, designing, processing, testing, and offering after-sale services ensures that customers receive the support they need to maximize production efficiency. This comprehensive support helps extend the lifespan of the equipment and ensures that customers can rely on their ERW tube mills for consistent, high-quality production.

The packing and shipping process for ERW tube mill lines is a critical aspect of ensuring that the equipment arrives safely and ready for installation. This process typically involves careful disassembly and protective packaging to prevent damage during transit. By disassembling parts into manageable sections, manufacturers can ensure easier handling and transport.

Protective packaging methods such as using wooden crates, shrink wrapping, and custom pallets are commonly employed to safeguard components during shipping. These methods ensure that each disassembled part is safe from damage and can be easily reassembled upon arrival at the destination.

Common packaging methods for ERW tube mill lines include protective wraps, wooden crates, and custom pallets to ensure component safety during shipping. These methods prevent damage and ensure the equipment arrives in optimal condition, ready for installation and commissioning.

Employing these protective packaging methods minimizes the risk of damage during transit, ensuring each component is securely packed and protected. This attention to detail is crucial for maintaining the quality and integrity of ERW tube mill lines.

Various shipping options are available for ERW tube mill lines, accommodating both domestic and international transportation. These options include road, rail, and ocean freight, ensuring that the equipment can be delivered safely and efficiently to its destination. Considerations such as international customs and regulations are taken into account to ensure smooth and hassle-free shipping.

Offering a range of shipping options allows manufacturers to provide flexible solutions that meet customer needs. This ensures timely delivery of ERW tube mill lines, ready for installation and operation.

Real-world examples of successful ERW tube mill line installations provide valuable insights into their impact across various industries. From construction and automotive to furniture manufacturing, ERW tube mills have proven essential for producing high-quality steel pipes that meet industry-specific needs. These case studies highlight the efficiency, precision, and adaptability of ERW tube mill lines.

Comprehensive after-sales support plays a crucial role in ensuring the longevity and efficient operation of ERW tube mill lines. This support includes:

These services help customers maximize production efficiency and maintain optimal machine performance.

ERW tube mill lines play a crucial role in producing high-quality steel pipes for various industries. In the construction industry, these production lines are essential for creating scaffolding and structural frames, providing the necessary support for building projects. The automotive industry also relies on ERW tube mills to produce precise exhaust systems that ensure durability and performance.

The furniture manufacturing industry uses ERW tubes to create strong and aesthetically pleasing frames, showcasing the versatility of these production lines that are formed by advanced techniques. In the chemical industry, ERW tube mills are critical for producing reliable piping systems that can withstand high pressures and corrosive materials.

These case studies showcase the diverse applications and benefits of ERW tube mill lines across different industries.

Many customers have expressed high levels of satisfaction with their ERW tube mill line installations, emphasizing the reliability and performance of the equipment. Clients report that the operational efficiency of ERW tube mill lines has significantly improved their production capacity, allowing them to meet higher demand and maintain competitive production schedules.

Customer feedback highlights the enhanced quality of finished products, leading to higher client satisfaction. The automation and efficiency of ERW tube mill lines have reduced production costs and improved product quality, making them a valuable asset for manufacturers across various industries.

When it comes to choosing the best ERW tube mill line manufacturer in China, SRET Co., Ltd. stands out as a leader in the field. SRET enjoys a strong reputation for innovation and excellence, providing high-quality ERW tube mill lines that meet the diverse needs of various industries. Their commitment to quality and customer satisfaction has made them a trusted name in the market.

SRET’s competitive edge lies in its ability to offer customized solutions tailored to specific customer requirements. Leveraging advanced technology and automation systems, SRET ensures high production efficiency, precision, and reliability in their ERW tube mill lines. This focus on innovation and customer-centric solutions sets SRET apart from other manufacturers.

Additional advantages of choosing SRET include comprehensive after-sales support, such as:

Providing a full range of services ensures customers receive the assistance needed to maintain optimal machine performance and maximize production efficiency. This commitment to customer support further reinforces SRET’s position as the best ERW tube mill line manufacturer in China.

In summary, ERW tube mill lines are a game-changer in the pipe manufacturing industry, offering high production efficiency, precision, and cost-effectiveness. From the initial preparation of steel coils to the final cutting and finishing of the tubes, each step in the ERW tube mill line process is meticulously designed to ensure the highest standards of quality and efficiency. The ability to customize these production lines to meet specific customer requirements further enhances their versatility and appeal.

Choosing the right manufacturer is crucial for ensuring the success of your ERW tube mill line installation. SRET Co., Ltd. stands out as the best manufacturer in China, offering high-quality products, advanced technology integration, and comprehensive after-sales support. By selecting SRET, you can be confident in the reliability and performance of your ERW tube mill line, ensuring that you meet the demands of your industry and achieve your production goals.

An ERW tube mill line is a manufacturing setup designed for producing pipes through electric resistance welding, where steel strips are joined at the edges via pressure and electric current to form a robust, continuous weld seam. This technology ensures high-quality pipe production for various applications.

The key components of an ERW tube mill line consist of the steel coil, forming rolls, weld seams, and automation equipment, all essential for the efficient manufacturing of high-quality pipes. These elements work in harmony to optimize production processes.

ERW tubes are commonly utilized in construction, automotive, furniture manufacturing, and the chemical industry due to their reliable and durable piping capabilities. This versatility underscores their significance in multiple sectors.

The use of ERW tube mill lines offers significant advantages such as high production efficiency, precise quality control, and cost-effectiveness, making them ideal for manufacturing high-quality steel pipes.

Choosing SRET Co., Ltd. for ERW tube mill lines guarantees high-quality products, advanced technology integration, and reliable after-sales support. Their reputation as a leading manufacturer in China solidifies their position as the optimal choice for your manufacturing needs.