SRET was founded in Shenyang, Liaoning province, China, in the year of 1989, by 5 university senior professors, with a original mindset of being a industrial pioneer of China’s tube mill machine manufacturing. For the past 30 years, SRET has remained the industrial leadership with continuous innovation and quality improvement. Today, SRET designs, engineers, manufactures, and supplies a full range of ERW tube mill machinery that satisfies your variety of application needs.

3 decades of experience and expertise distinguish SRET from the other competitors. A highly qualified engineering team and experienced production team assure that exactly the equipment desired is delivered to the customer. Our pipe & tube mill machinery promise the top quality performance and production of high grade tubes. Everyday, we work hard to meet the rigorous engineering and design expectations that the clients come to value.

Philosophy

Every client is unique, every solution is different. Assuring a complete customer satisfaction is set to be the first priority at SRET. To this end, it always distills down to a single word: Trust. SRET upholds the highest standards of INTEGRITY at all times.

Integration A professional team for project integration management coordinating all elements of the project to ensure the delivery of the entire tube mill on time, specifications, and budget. The seamless combination and coordination of various processes, equipment, and systems can achieve efficient tube production. And we are able to create a cohesive production ecosystem where all elements work together to deliver high-quality tubes with minimum waste and maximum reliability.

A professional team for project integration management coordinating all elements of the project to ensure the delivery of the entire tube mill on time, specifications, and budget. The seamless combination and coordination of various processes, equipment, and systems can achieve efficient tube production. And we are able to create a cohesive production ecosystem where all elements work together to deliver high-quality tubes with minimum waste and maximum reliability.

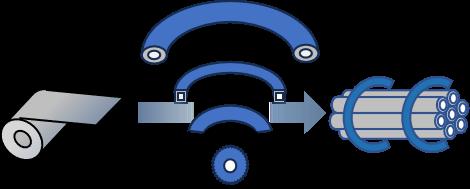

Automation

Adoption of automatic control systems and intelligent equipment realizes the automated production process from raw material feeding, pipe forming, welding, sizing, cutting to quality inspection. It also reduces labor intensity and costs by replacing labor-intensive tasks, requiring fewer workers who can shift to value-added roles like maintenance and supervision. Meanwhile, tube-mil tailored MES provides manufacturing plan & control, cost management, quality control, and more upon request.

Adoption of automatic control systems and intelligent equipment realizes the automated production process from raw material feeding, pipe forming, welding, sizing, cutting to quality inspection. It also reduces labor intensity and costs by replacing labor-intensive tasks, requiring fewer workers who can shift to value-added roles like maintenance and supervision. Meanwhile, tube-mil tailored MES provides manufacturing plan & control, cost management, quality control, and more upon request.

Whether one machine or entire tube mill line, SRET is the right supplier you may trust for help. Our goal is to provide pipe & tube manufacturer with technologies and solutions to achieve ultimate product quality, reduced operation expenses, and subsequent competitiveness. SRET is proud of its extensive know-how of ERW tube & pipe manufacturing industry, which comes from its hand-on experience on designing, engineering, and commissioning of hundreds of pipe & tube mill equipments or complete lines for customers from over 40 countries across continents.