The global steel pipe industry relies heavily on Electric Resistance Welded (ERW) tube mills for efficient, high-volume production of quality pipes. As infrastructure projects expand worldwide and industrial applications continue to grow, selecting the right erw tube mill manufacturer becomes crucial for businesses looking to establish or upgrade their pipe manufacturing capabilities.

ERW tube mills represent one of the most cost-effective and versatile solutions for producing welded pipes across various industries. From construction and automotive to oil and gas transportation, these sophisticated production lines deliver the precision and efficiency needed to meet modern manufacturing demands.

In this comprehensive guide, we’ll explore the leading ERW tube mill manufacturers worldwide, examine the technology behind these systems, and provide essential insights for making informed purchasing decisions that align with your production goals and budget requirements.

The global market for ERW tube mill equipment features several established manufacturers with proven track records in delivering reliable, high-performance production lines. Understanding the capabilities and specializations of these key suppliers helps ensure you partner with a company that can meet your specific manufacturing requirements.

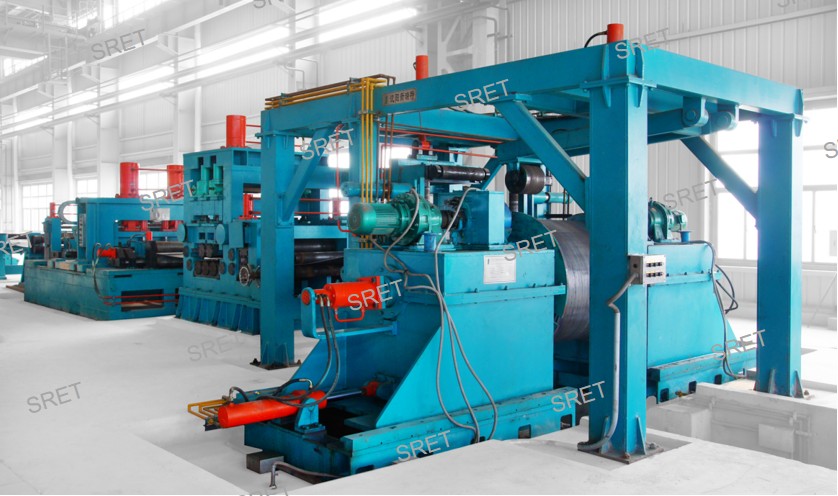

SRET was founded in Shenyang, Liaoning province, China, in the year of 1989, by 5 university senior professors, with a original mindset of being a industrial pioneer of China’s tube mill machine manufacturing. For the past 30 years, SRET has remained the industrial leadership with continuous innovation and quality improvement. Today, SRET designs, engineers, manufactures, and supplies a full range of ERW tube mill machinery that satisfies your variety of application needs. 3 decades of experience and expertise distinguish SRET from the other competitors. A highly qualified engineering team and experienced production team assure that exactly the equipment desired is delivered to the customer. Our pipe & tube mill machinery promise the top quality performance and production of high grade tubes. Everyday, we work hard to meet the rigorous engineering and design expectations that the clients come to value.

Electric Resistance Welding tube mill technology represents a sophisticated approach to continuous pipe production that combines efficiency with precision. The ERW process transforms flat steel strips into tubular products through a carefully orchestrated sequence of forming and welding operations.

The core manufacturing process begins with uncoiling steel strips, which are then progressively formed into tubular shapes through a series of forming stands. High-frequency induction welding creates a continuous longitudinal seam, followed by sizing operations to achieve precise dimensional accuracy and cutting to specified lengths.

ERW technology differs significantly from other welding methods in pipe production. Unlike submerged arc welding or spiral welding processes, ERW uses electrical resistance to generate the heat needed for welding, resulting in faster production speeds and more energy-efficient operation. This method produces a narrow heat-affected zone, preserving the base material properties while creating strong, reliable welds.

Material compatibility extends beyond traditional carbon steel to include stainless steel, aluminum, and various copper alloys. This versatility allows manufacturers to serve diverse market segments with a single production line, maximizing equipment utilization and return on investment.

Current ERW tube mill technology supports production capabilities ranging from 8mm to 89mm outer diameter (od) with wall thickness specifications up to 4.5mm. These ranges cover the majority of applications in construction, automotive, and general manufacturing industries.

Modern ERW tube mill machines deliver impressive production capabilities designed to meet the demands of high-volume manufacturing environments. Production speed ranges typically span from 20 to 120 meters per minute, allowing manufacturers to achieve substantial daily output while maintaining consistent quality standards.

The versatility of contemporary tube mill equipment extends to pipe shape production beyond traditional round configurations. Advanced forming systems can produce square, rectangular, oval, and custom abnormal tubes, providing manufacturers with the flexibility to serve specialized market segments and unique customer requirements.

Diameter accuracy represents a critical performance metric, with leading equipment achieving tolerances within 0.5% of target specifications. This level of precision ensures consistent product quality and reduces downstream processing requirements, contributing to overall manufacturing efficiency.

Automatic operation capabilities minimize the need for manual intervention during normal production runs. Sophisticated control systems monitor critical parameters continuously, making real-time adjustments to maintain optimal operating conditions and product quality. These automated features also contribute to improved workplace safety by reducing operator exposure to potentially hazardous equipment areas.

Quick roller change systems represent a significant advancement in production flexibility. Modern designs allow complete roller changeovers in approximately 10 minutes, with production resumption typically occurring within 20 minutes. This rapid changeover capability enables manufacturers to respond quickly to varying customer demands and maintain high equipment utilization rates.

The straightening capabilities of modern equipment ensure that finished pipes meet demanding dimensional requirements for industrial applications. Integrated straightening systems correct any minor deviations that may occur during the forming process, delivering products ready for immediate use or further processing.

A comprehensive ERW tube mill production line integrates multiple specialized components working in coordination to transform raw steel coils into finished pipes. Understanding these components helps manufacturers evaluate equipment offerings and plan facility layouts effectively.

The production process begins with strip preparation equipment designed to handle various coil sizes and materials. Slitting machines convert wide steel coils into narrower strips suitable for pipe production, while uncoilers provide consistent material feed throughout the production cycle.

Feeding systems ensure smooth, continuous material flow into the forming section, incorporating features like strip accumulators that allow for coil changes without interrupting production. These accumulator systems significantly improve overall equipment effectiveness by minimizing downtime.

The forming section represents the heart of ERW tube mills, where flat strips are progressively shaped into tubular form. Pinch rolls provide initial strip control, while guide rolls ensure proper alignment throughout the forming process.

Progressive forming stations gradually bend the strip edges together, creating the precise edge preparation needed for high-quality welding. The number and configuration of forming stations directly impact the maximum wall thickness and material types that can be processed effectively.

High-frequency induction generators supply the energy needed for ERW welding, operating at frequencies optimized for efficient heating and minimal material distortion. Modern HF systems incorporate advanced power control features that automatically adjust output based on production speed and material characteristics.

Cooling equipment immediately follows the welding station, rapidly reducing material temperature to prevent heat-related distortion and prepare the pipe for downstream processing. Proper cooling system design is essential for maintaining dimensional accuracy and material properties.

Sizing mills provide final dimensional control, ensuring that finished pipes meet specified outer diameter and wall thickness requirements. These precision machines can accommodate minor variations in incoming material and welding process conditions.

Straightening equipment corrects any residual curvature resulting from the forming and welding processes. Modern straightening systems use sophisticated algorithms to determine optimal correction forces, minimizing the risk of over-correction or material damage.

Cutting systems divide the continuous pipe into specified lengths, with options ranging from simple flying cut-off machines to sophisticated systems capable of precise length control and end finishing. Advanced cutting systems can accommodate complex cutting schedules and maintain tight length tolerances.

Take-off systems provide controlled removal of finished pipes from the production line, with capabilities for handling various pipe sizes and weights safely. These systems often incorporate automatic stacking or packaging features that prepare products for shipment.

Packaging equipment options range from simple bundling systems to sophisticated automated packaging lines that can handle multiple pipe sizes and prepare products according to customer specifications.

HR coil slitting lines serve as essential preparation equipment for ERW tube mill operations, particularly when processing wide steel coils that must be divided into multiple narrower strips. These integrated systems include uncoiler, feeder, pinch, pre-leveler, cropping shear, and recoiler components.

The capability to process various non-ferrous metal coils with different slitting tools expands production possibilities beyond traditional carbon steel applications. This flexibility proves particularly valuable for manufacturers serving diverse market segments or planning future product line expansions.

Slitting machine integration ensures consistent strip quality entering the tube mill, directly impacting final product quality and production efficiency. Proper strip preparation eliminates many potential downstream problems and contributes to smooth, uninterrupted production runs.

The complete steel pipe production workflow follows a carefully optimized sequence: uncoiling, welding, forming, cooling, sizing, cutting, and packing. Each stage contributes to final product quality and production efficiency, requiring precise coordination and control.

High-frequency longitudinal welding creates superior joint quality and strength compared to alternative welding methods. The concentrated heat input minimizes the heat-affected zone while ensuring complete fusion across the weld seam. This approach preserves base material properties while creating joints that often exceed the strength of the parent material.

Precision forming techniques maintain consistent wall thickness throughout the pipe length, critical for applications requiring uniform structural properties. Advanced forming roll designs distribute forming forces evenly, preventing localized thinning or thickening that could compromise product performance.

Quality control systems integrated throughout the production line ensure minimal wastage and high production efficiency. Real-time monitoring of critical parameters enables immediate correction of any deviations, preventing the production of non-conforming products and reducing material waste.

Turnkey project capabilities offered by leading manufacturers include technical consultation and equipment modification services. These comprehensive packages ensure that clients receive systems optimized for their specific requirements and operating conditions, maximizing return on investment.

The entire production process operates under computer control, with programmable logic controllers coordinating all major functions. This automation level enables consistent product quality while reducing labor requirements and improving workplace safety.

ERW tube mills serve a diverse range of industries, each with specific requirements for pipe dimensions, materials, and quality standards. Understanding these applications helps manufacturers select equipment configurations that maximize market opportunities.

Construction and infrastructure projects represent the largest market segment for ERW pipe products. These applications require structural pipes and hollow sections that provide strength, durability, and cost-effectiveness for buildings, bridges, and other infrastructure elements.

The automotive industry demands precision tubes for vehicle manufacturing, including components for exhaust systems, chassis elements, and hydraulic applications. The tight tolerances and consistent quality achievable with modern ERW technology make these systems ideal for automotive supply chains.

Machinery and equipment manufacturing utilizes ERW pipes for hydraulic and pneumatic systems where dimensional accuracy and surface finish directly impact performance. The ability to produce specialized shapes and sizes enables equipment manufacturers to optimize their designs for specific applications.

Oil and gas industry applications include transmission pipelines and processing equipment where strength, corrosion resistance, and dimensional accuracy are critical. ERW technology can accommodate the specialized materials and coating requirements common in this sector.

Manufacturing of galvanized steel pipes, black pipes, and high-strength steel tubes represents additional market opportunities. The versatility of ERW equipment allows producers to serve multiple market segments with appropriate material and finishing modifications.

Experience and track record serve as fundamental criteria when evaluating potential suppliers. Manufacturers with 20+ years in the industry typically possess the depth of knowledge needed to address complex technical challenges and provide reliable long-term support.

Technical capabilities extend beyond equipment design to include research and development resources. Companies maintaining R&D teams with 30+ engineers demonstrate commitment to continuous improvement and technological advancement. Comprehensive after-sales support ensures ongoing equipment performance and production efficiency.

Production capacity and facility size indicate a manufacturer’s ability to meet large-scale manufacturing demands and delivery schedules. Substantial facilities also suggest financial stability and commitment to the industry, important factors for long-term supplier relationships.

Customization options enable manufacturers to specify equipment configurations for specific pipe sizes, materials, and production requirements. The ability to modify standard designs ensures optimal performance for unique applications and market requirements.

Global service networks providing installation, commissioning, and maintenance support are essential for international projects. Local service capabilities reduce response times and minimize production disruptions when technical support is needed.

Certification and quality standards compliance ensures equipment meets international requirements and facilitates export opportunities. ISO certifications and compliance with industry-specific standards demonstrate manufacturer commitment to quality and reliability.

When evaluating potential suppliers, consider their ability to provide complete turnkey solutions including facility design, equipment installation, operator training, and ongoing technical support. This comprehensive approach simplifies project management and ensures system optimization.

Low unit wastage design reduces material costs and environmental impact, contributing to sustainable manufacturing practices. Modern ERW equipment typically achieves material utilization rates exceeding 98%, significantly reducing raw material requirements compared to alternative production methods.

High-speed production capabilities directly impact profitability by maximizing output from available labor and facility resources. The ability to produce 100+ meters per minute enables manufacturers to achieve substantial daily production volumes while maintaining consistent quality.

Reduced manual labor requirements through automated operation systems lower ongoing operational costs and improve workplace safety. Advanced control systems handle routine monitoring and adjustment tasks, allowing operators to focus on quality control and equipment optimization.

Long-term durability and reliability minimize maintenance expenses over equipment life cycles. Quality ERW tube mills often operate effectively for decades with proper maintenance, providing excellent return on investment for capital expenditures.

Energy-efficient HF welding technology contributes to sustainable manufacturing by reducing power consumption compared to alternative welding methods. The concentrated heating approach requires less total energy input while achieving superior weld quality.

The combination of high production speeds, minimal wastage, and reduced labor requirements creates compelling economic advantages for ERW tube mill operations. These factors enable manufacturers to compete effectively in global markets while maintaining healthy profit margins.

Advanced sizing and cutting capabilities reduce or eliminate secondary processing requirements, further improving cost efficiency. Products meeting final specifications directly from the tube mill reduce handling costs and delivery times to customers.

Modern ERW tube mill technology represents a mature, proven approach to efficient pipe manufacturing. The combination of technological sophistication, production efficiency, and economic benefits makes these systems attractive investments for companies entering the pipe manufacturing market or upgrading existing capabilities.

Selecting the right erw tube mill manufacturer requires careful evaluation of technical capabilities, experience, and support services. The leading suppliers profiled in this guide offer proven solutions backed by decades of industry experience and comprehensive customer support.

Whether you’re planning a new facility or upgrading existing equipment, partnering with an established manufacturer ensures access to the latest technology and ongoing support needed for successful pipe manufacturing operations. Contact multiple suppliers to compare capabilities and obtain detailed quotes tailored to your specific production requirements.