An ERW tube mill uses electric resistance welding to turn steel strips into high-quality tubes. This process is vital for industries needing strong and precise steel pipes. This article covers how ERW tube mills work, their benefits, applications, and recent advancements.

ERW Tube Mills are advanced facilities that utilize electric resistance welding to produce high-quality steel pipes from flat strips or coils of steel. These mills are the cornerstone of the steel industry, transforming raw steel strips into robust and reliable welded tubes through a series of meticulously controlled processes. The electric resistance welding process is at the heart of these mills, ensuring that the steel pipes produced are not only strong but also consistent in quality and dimensions.

Knowing the production requirements, including tube dimensions and materials, is vital when choosing a tube mill. This understanding allows the ERW mill to cater to various specific customer requirements, from small-diameter pipes for automotive fuel lines to large-diameter tubes for oil and gas pipelines.

Customizable production parameters make manufactured ERW tube mills versatile and indispensable in the steel industry.

The production process in ERW Tube Mills involves forming flat steel strips into cylindrical shapes and fusing their edges through high-frequency electrical currents. This method, known as electric resistance welding, is renowned for its efficiency and precision. It starts with the careful preparation of steel strips, which are shaped and welded into strong, consistent tubes. High-frequency currents heat and press the steel strip edges together, creating a robust weld seam.

The electric resistance welding process ensures the structural integrity and quality of the finished ERW tubes. A precise and controlled environment produces welded tubes that meet stringent industry standards, resulting in high-strength, reliable ERW pipes suitable for various applications.

The quality of raw materials flat strip steel strips directly affects the durability and integrity of the final welded pipes. Variations in strip quality can cause defects, so starting with high-grade materials is vital.

The uncoiler feeds steel strips into the tube mill by unwinding them into a flat coil form, ensuring a continuous and smooth material flow into the production line.

The strip-head shear and butt welder align and join steel strip ends, creating a continuous feed for the production process. This method ensures uninterrupted steel pipe production, maintaining high-speed production rates and tube mill efficiency.

Forming rolls:

The forming and sizing mill section shapes the steel strip into a tube, ensuring it meets precise dimensional specifications. This step is crucial for producing high-quality pipes that fit perfectly in their intended applications.

High-frequency welding uses electric current to heat the steel strip edges, forming a strong bond. This process rapidly heats the edges, enabling a quick and robust weld seam fusion.

This method produces high-quality pipes with a strong weld seam, essential for applications requiring high strength and durability. The highly automated production line enables high-speed ERW tube production, making the process efficient and cost-effective.

ERW tubes are cost effectiveness due to:

ERW tubes are produced at high speeds, enhancing the overall efficiency and responsiveness of manufacturing processes. This capability allows manufacturers to quickly and efficiently meet the growing demand for steel pipes, making ERW tubes a preferred option for many applications.

ERW Tube Mills can produce tubes in various shapes and sizes, making them essential for various industries including construction and oil and gas. In the automotive sector, ERW tubes are used for structural support by structural engineers due to their strength and durability, often outperforming traditional materials like PVC. These tubes are commonly employed in vehicle exhaust systems, resisting corrosion and thermal effects, enhancing engine performance.

ERW tubes are used in various vehicle systems:

ERW Tube Mills are designed for efficiency, leading to significant cost savings and optimized material use, minimizing waste. Recent developments focus on enhancing automation and digitalization, integrating IoT and AI for improved precision and efficiency. These world leading advancements allow real-time monitoring and adjustments during manufacturing, enhancing overall quality with the new erw mill.

Advancements in welding technology have resulted in better-quality weld seams that closely match the base material properties, ensuring high strength. Advanced control systems enable real-time monitoring and adjustments during manufacturing, enhancing overall quality.

Adopting the latest welding technology can enhance weld strength and uniformity in tube production.

The electric resistance welding process begins by transforming flat steel strips into tubular shapes through a series of precise operations.

Key aspects include:

Automatic stacking and packing machine enhance productivity by automating the organization and packaging of finished products. These machines are essential for increasing efficiency and reducing manual labor, ensuring the final welded tubes are ready for shipment and use in various applications.

High-quality welded tubes produced by ERW Tube Mills meet stringent industry standards, ensuring durability and reliability in their applications. Maintaining precise dimensional tolerance is crucial for ensuring the proper fit and integrity of ERW pipes. Dimensional tolerance includes acceptable variations in physical measurements like outer diameter, wall thickness, and length, which are vital for installation accuracy.

Reputable manufacturers routinely use:

Modern ERW mills offer several advantages:

The environmental benefits of ERW steel pipes include:

Choosing the right ERW tube mill manufacturer is crucial for ensuring quality and efficiency in production. Consider the following factors when selecting a manufacturer:

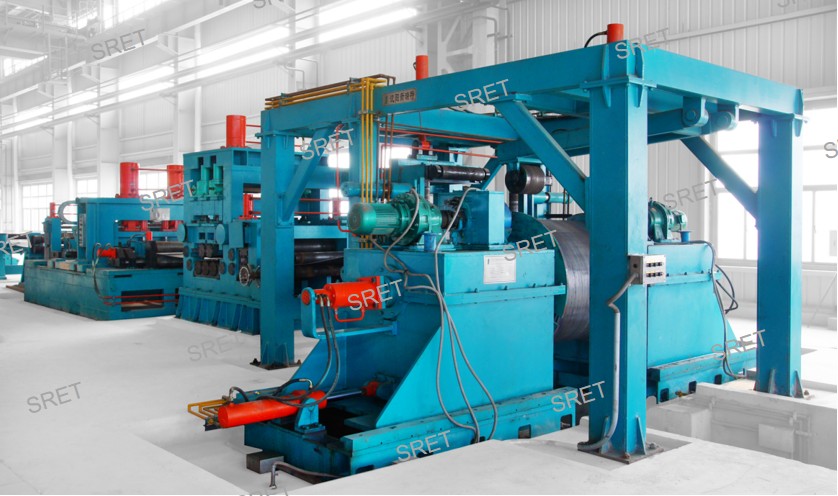

Founded in 1989 by five university senior professors in Shenyang, Liaoning province, China, SRET stands out as a leading manufacturer of ERW tube mill machinery. With over three decades of experience, SRET designs, engineers, manufactures, and supplies a full range of ERW tube mill machinery for various application needs.

Their commitment to innovation and quality improvement ensures their equipment delivers top-quality performance and high-grade tube production. Choosing SRET means benefiting from their extensive expertise and highly qualified engineering and production teams, guaranteeing the delivery of precise equipment to customers.

In summary, ERW tube mills are a cornerstone of modern steel pipe production, offering unmatched efficiency, precision, and versatility. From the initial stages of handling steel strips to the final quality control measures, every aspect of the ERW tube production process is meticulously managed to ensure the highest quality of welded tubes. The advancements in technology, automation, and digitalization have further enhanced the capabilities of ERW tube mills, making them indispensable in various industries.

As we move forward, the importance of sustainability and environmental impact cannot be overstated. Modern ERW mills are designed to minimize energy consumption and waste, contributing to more sustainable manufacturing practices. Choosing the right ERW tube mill manufacturer, such as SRET, is critical for ensuring quality, efficiency, and long-term success in the steel industry. By understanding the intricacies of ERW tube mills, we can appreciate the technological marvels that drive our world forward.

Electric resistance welding (ERW) plays a vital role in tube production by creating strong, reliable weld seams that enhance the durability of steel pipes. This process is essential for ensuring the structural integrity and quality of the final product.

The quality of steel strips is crucial in ERW tube production as it directly affects the strength and integrity of the final welded tubes, preventing defects that could compromise their performance.

Forming rolls are essential in ERW tube production as they systematically bend flat steel strips into cylindrical shapes, ensuring both dimensional accuracy and readiness for the welding phase. This process is crucial for producing high-quality welded tubes.

ERW tubes are widely applied in the automotive industry for structural support, exhaust systems, and fuel delivery systems, as well as in construction projects and various components like radiators and condensers. Their versatility makes them integral across these sectors.

Choosing the right ERW tube mill manufacturer is crucial as it directly affects the reliability, efficiency, and quality of production. A reputable manufacturer significantly enhances the overall production process and the quality of the final product.